You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Latest in progress from AHG

- Thread starter AcornHouse

- Start date

- Joined

- Jul 30, 2007

- Messages

- 13,670

- Reaction score

- 3,101

- Location

- Philly, or thereabouts

- Guild Total

- 11

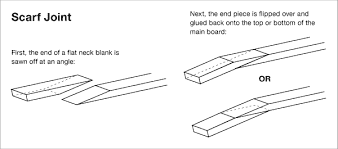

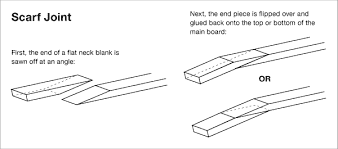

Is having the spliced headstock on the bottom stronger than having it on the top, or is that just a tradition?

AcornHouse

Venerated Member

I think it is stronger. You get the advantage of the overlay supporting both pieces just about equally. And the scarf joint is all in the headstock, where it can easily be minimized visually by the tuners or, in the case of a steel string, by the added wing pieces (which will also further lock things together for additional strength.)Is having the spliced headstock on the bottom stronger than having it on the top, or is that just a tradition?

When you do it the other way, the joint is right in the neck where you can’t miss it.

- Joined

- Jul 30, 2007

- Messages

- 13,670

- Reaction score

- 3,101

- Location

- Philly, or thereabouts

- Guild Total

- 11

Ok, sounds like a plan.

AcornHouse

Venerated Member

Chris, this is a really interesting and fun thread!

walrus

walrus

Lookin' good, Chris!

Opsimath

Senior Member

Does sanded to 180 mean 180 degrees? A straight line?

Sorry for an uninformed question but my knowledge of woodworking and guitar building hover right around zero.

Sorry for an uninformed question but my knowledge of woodworking and guitar building hover right around zero.

AcornHouse

Venerated Member

No problem. 180 grit sandpaper. Which in the carpentry world would be considered fine or extra fine, since they typically would go to 120 grit on trim work. (The higher number, the finer the grit. Essentially how many particles per square inch, iirc.)Does sanded to 180 mean 180 degrees? A straight line?

Sorry for an uninformed question but my knowledge of woodworking and guitar building hover right around zero.

For luthiery, we will typically go much higher. 320 or 400 for surfaces that will be varnished and upwards of 12000 on those woods, like ebony, that can get a mirror shine without any finish at all.

Opsimath

Senior Member

Thank you for the explanation. Sandpaper didn't occur to me.No problem. 180 grit sandpaper. Which in the carpentry world would be considered fine or extra fine, since they typically would go to 120 grit on trim work. (The higher number, the finer the grit. Essentially how many particles per square inch, iirc.)

For luthiery, we will typically go much higher. 320 or 400 for surfaces that will be varnished and upwards of 12000 on those woods, like ebony, that can get a mirror shine without any finish at all.

AcornHouse

Venerated Member

After using a hand plane to get the angle on the sides, and drilling the end point for the slots, I use a coping saw to rough cut out the interior.

Then I break out my favorite vintage Stanley paring chisel and a straight edge jig to pare them to finished (bar sanding) shape. (I’ll also be ramping them to let the strings through to the nut.)

Then I break out my favorite vintage Stanley paring chisel and a straight edge jig to pare them to finished (bar sanding) shape. (I’ll also be ramping them to let the strings through to the nut.)

- Joined

- Jul 30, 2007

- Messages

- 13,670

- Reaction score

- 3,101

- Location

- Philly, or thereabouts

- Guild Total

- 11

Just Chris 'n' Chris!No CNC machines here!

AcornHouse

Venerated Member

Not banned, but routers are a good way for things to go very bad in an instant. And in the case of these slots, one of the big issues is where to clamp a template. Plus, doing it by hand is quicker than the multiple router setups required.Are electrical tools banned - or is there another reason for not using router to make those slots ?

With guitars, electric guitars are more power tool friendly that acoustic guitars, and classical guitars are yet more hand tool intensive still.

AcornHouse

Venerated Member

AcornHouse

Venerated Member

Very, very nice work.I think it is stronger. You get the advantage of the overlay supporting both pieces just about equally. And the scarf joint is all in the headstock, where it can easily be minimized visually by the tuners or, in the case of a steel string, by the added wing pieces (which will also further lock things together for additional strength.)

When you do it the other way, the joint is right in the neck where you can’t miss it.

My physics could be wrong, but as you said, I believe the bottom one is stronger. On the upper one, the fulcrum is at the top of the fingerboard at the far end of the joint from the headstock, allowing for more force where the joint would open up. Wheras the fulcrum on the lower joint is at the headstock end of the joint, for less force where the joint would open.