You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

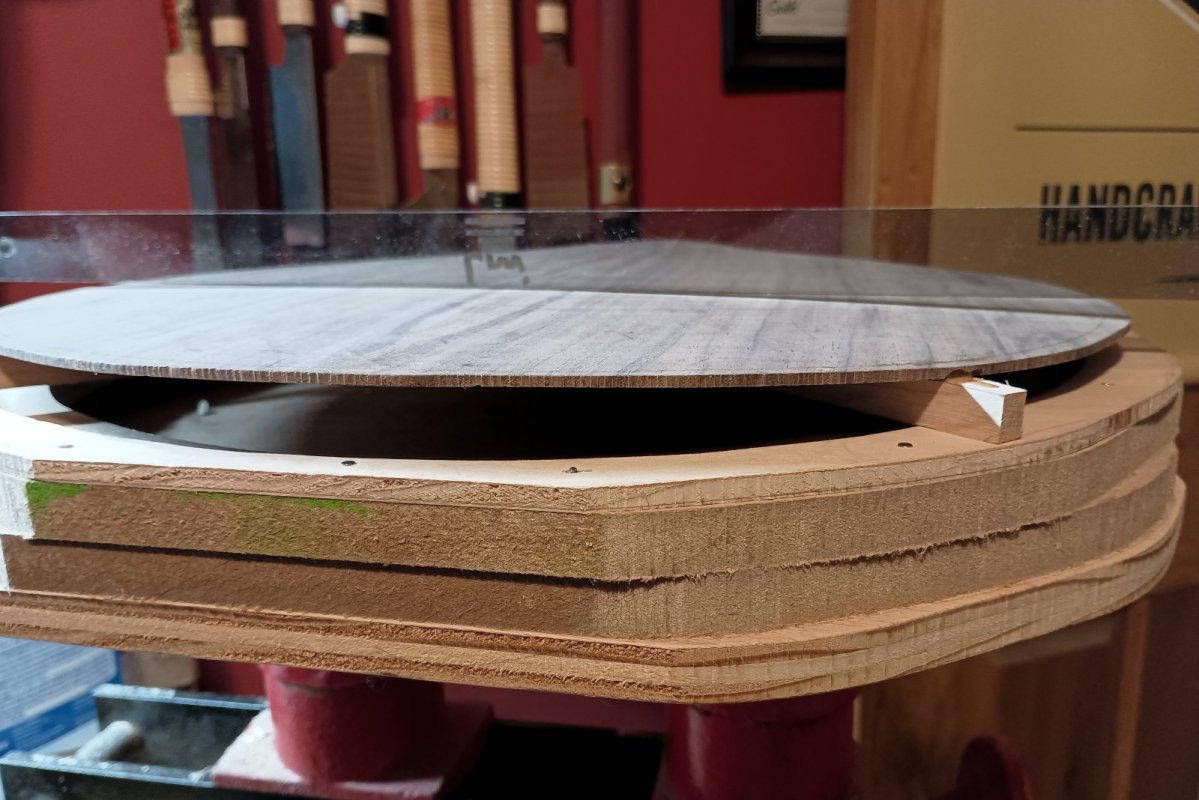

AHG octave mando build

- Thread starter AcornHouse

- Start date

AcornHouse

Venerated Member

No standard, but x-bracing has become more popular amongst modern builders. It makes sense for a more or less circular body shape.Is X-bracing the back unusual for mando family instruments or is there no standard for this?

AcornHouse

Venerated Member

AcornHouse

Venerated Member

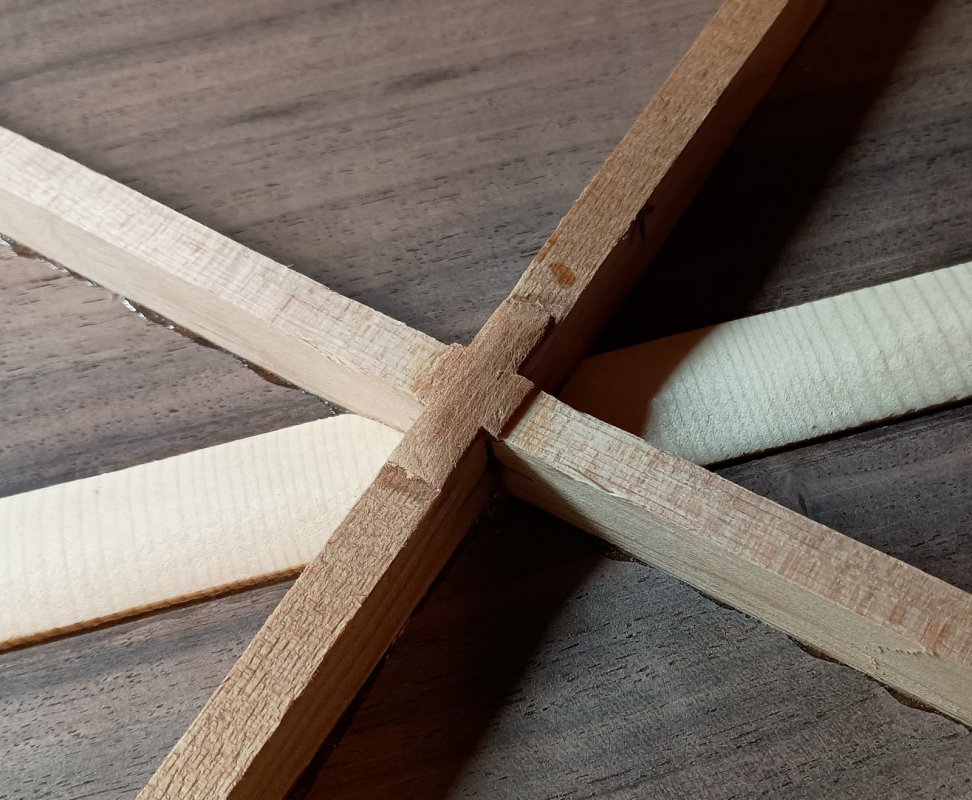

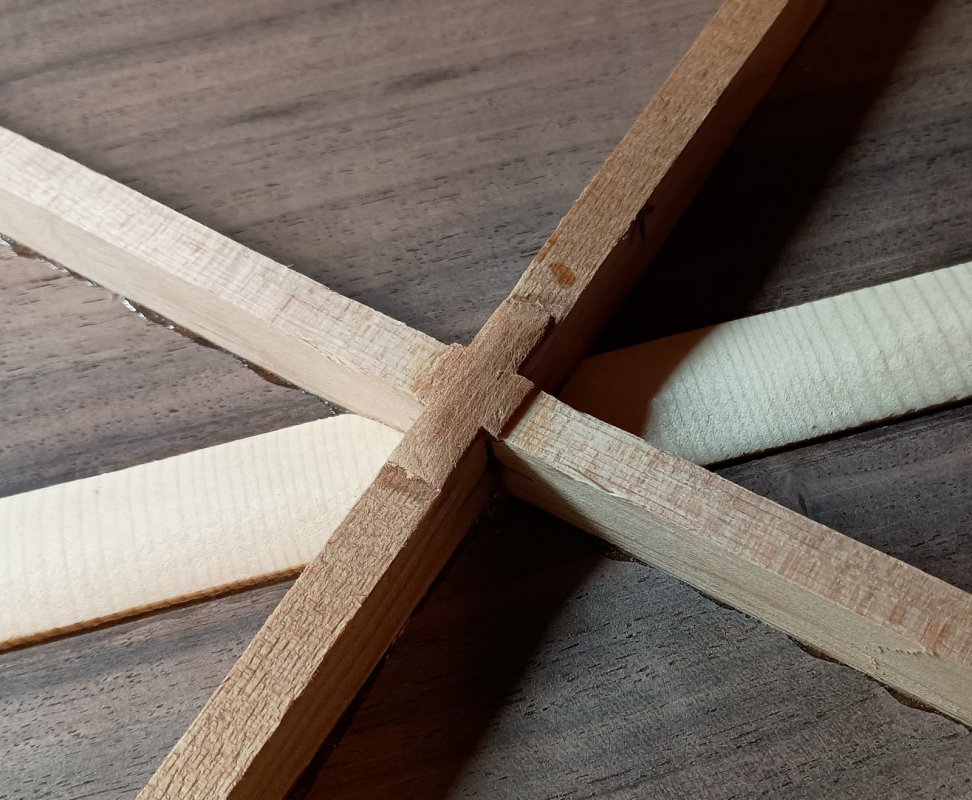

Quick little addition for today. A lap joint, used in all x-braves, has one major weak point in the arm that was cut with the open side facing up. At that point, the structural height is cut, literally, in half. Martin and other historical builders addressed this weakness by glueing a small patch of cloth, which doesn't really do much. Contemporary builders add a small bit of wood to bridge the gap and, effectively, restore the height and the full strength. It's the same principle as a plumber running a pipe through a beam. Do it in the middle and there's no problem. Notch it half way through and Grandma's sitting in a tub amidst a pile of debris one floor below.

Last edited:

Nuuska

Enlightened Member

Oh no ! ! !

Now my mind starts thinking of them forces acting at tha joint. And it is already half past midnight.

Forget about a loose back - concentrate on final box where sides provide stiff support.

I suppose - I REALLY do not know - that this x-connection is cut 50-50.

What if ?

What if the lower brace, that goes under, is cut deeper - like only 40% wood and upper crossing would have 60% wood ?

What are the forces influencing this joint?

Do they pull or push?

Or one pulls & other pushes?

Can I go to sleep?

Shall I have one more beer?

I'll leave it up to you - meanwhile I'll get one more beer and then hit the hay.

Nighty nite to ya'll

Now my mind starts thinking of them forces acting at tha joint. And it is already half past midnight.

Forget about a loose back - concentrate on final box where sides provide stiff support.

I suppose - I REALLY do not know - that this x-connection is cut 50-50.

What if ?

What if the lower brace, that goes under, is cut deeper - like only 40% wood and upper crossing would have 60% wood ?

What are the forces influencing this joint?

Do they pull or push?

Or one pulls & other pushes?

Can I go to sleep?

Shall I have one more beer?

I'll leave it up to you - meanwhile I'll get one more beer and then hit the hay.

Nighty nite to ya'll

AcornHouse

Venerated Member

Is your hay in square bales or large round bales?Oh no ! ! !

Now my mind starts thinking of them forces acting at tha joint. And it is already half past midnight.

Forget about a loose back - concentrate on final box where sides provide stiff support.

I suppose - I REALLY do not know - that this x-connection is cut 50-50.

What if ?

What if the lower brace, that goes under, is cut deeper - like only 40% wood and upper crossing would have 60% wood ?

What are the forces influencing this joint?

Do they pull or push?

Or one pulls & other pushes?

Can I go to sleep?

Shall I have one more beer?

I'll leave it up to you - meanwhile I'll get one more beer and then hit the hay.

Nighty nite to ya'll

Do cows prefer one over the other?

Is it easier to process square or round?

Why do you have to hit it, it didn’t do anything to you?

Should it just be left in haystack?

Will there always be a needle in a haystack, or do we have to supply our own?

Why would you even have a needle near a haystack?

AcornHouse

Venerated Member

- Joined

- Jul 30, 2007

- Messages

- 13,682

- Reaction score

- 3,117

- Location

- Philly, or thereabouts

- Guild Total

- 11

In the spring we sew seeds for the fall har vest.Is your hay in square bales or large round bales?

Do cows prefer one over the other?

Is it easier to process square or round?

Why do you have to hit it, it didn’t do anything to you?

Should it just be left in haystack?

Will there always be a needle in a haystack, or do we have to supply our own?

Why would you even have a needle near a haystack?

The Guilds of Grot

Enlightened Member

Everybody knows cows don't like round hay bales, they can't get a "square" meal!

Prince of Darkness

Senior Member

- Joined

- Feb 17, 2018

- Messages

- 3,650

- Reaction score

- 9,723

- Location

- Boddam, North East Scotland.

- Guild Total

- 2

AcornHouse

Venerated Member

AcornHouse

Venerated Member

AcornHouse

Venerated Member

AcornHouse

Venerated Member

- Joined

- Jul 30, 2007

- Messages

- 13,682

- Reaction score

- 3,117

- Location

- Philly, or thereabouts

- Guild Total

- 11

Fwiw, that pickup pegged the input on my buddy's interface.

AcornHouse

Venerated Member

Perfect to use with a Hi-Watt double stack.Fwiw, that pickup pegged the input on my buddy's interface.

Or this.

Last edited: