Router bit me again.

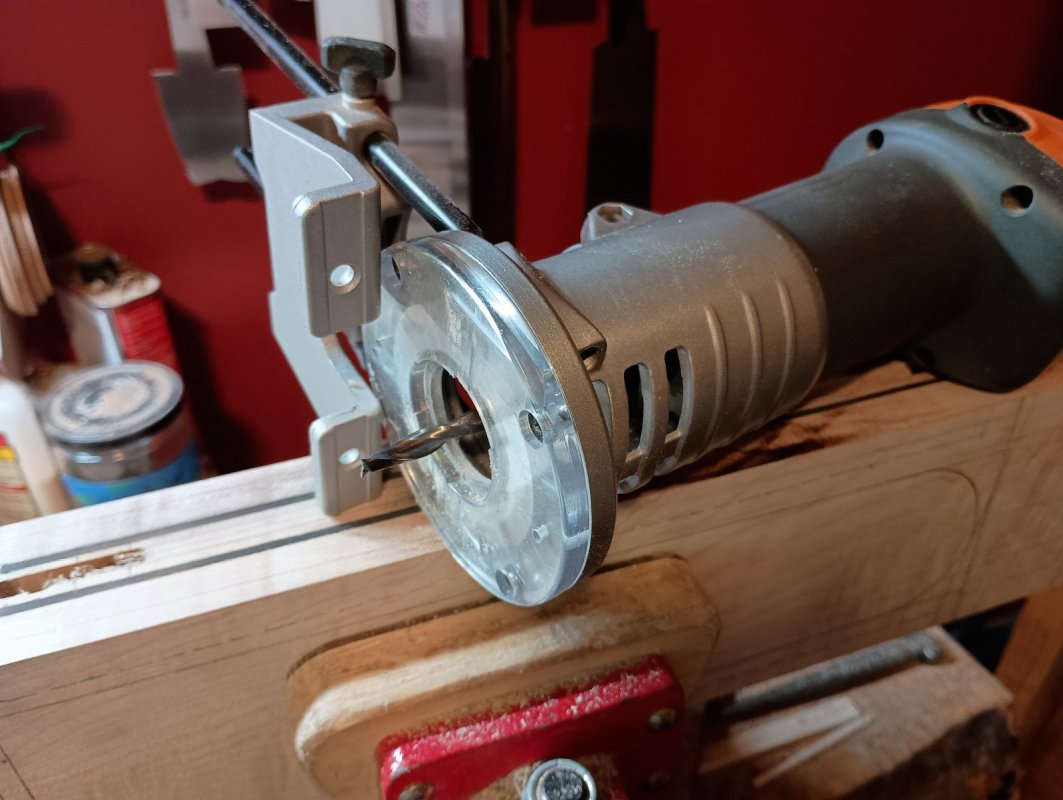

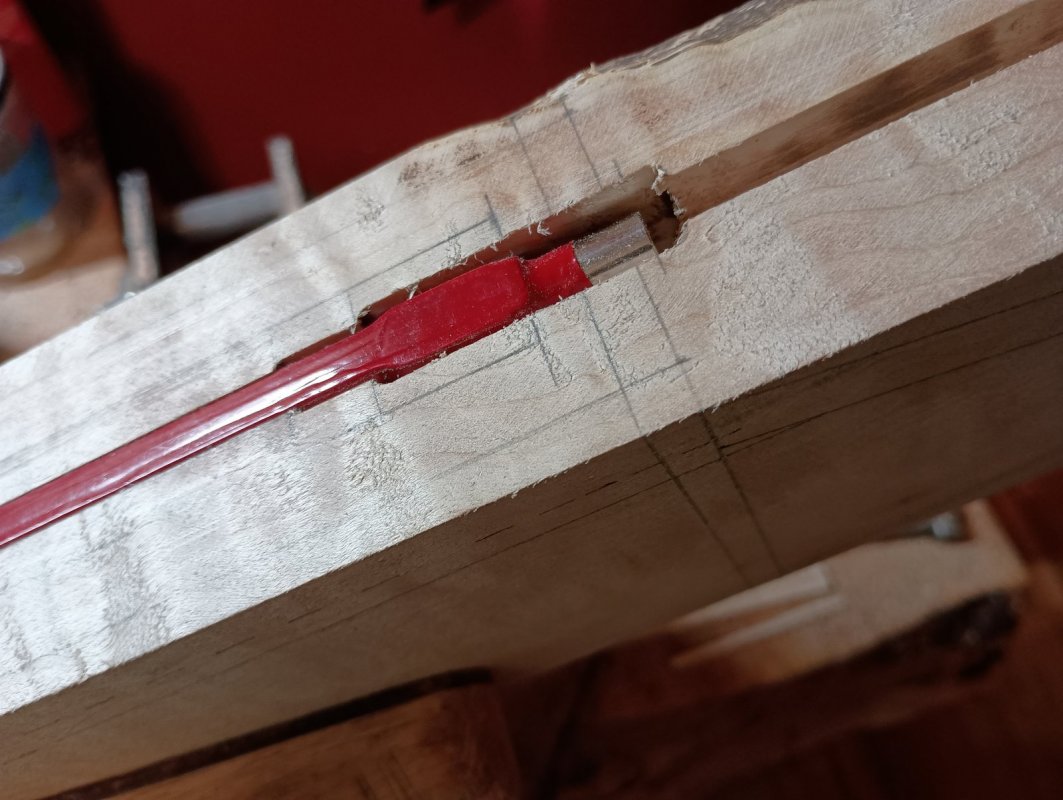

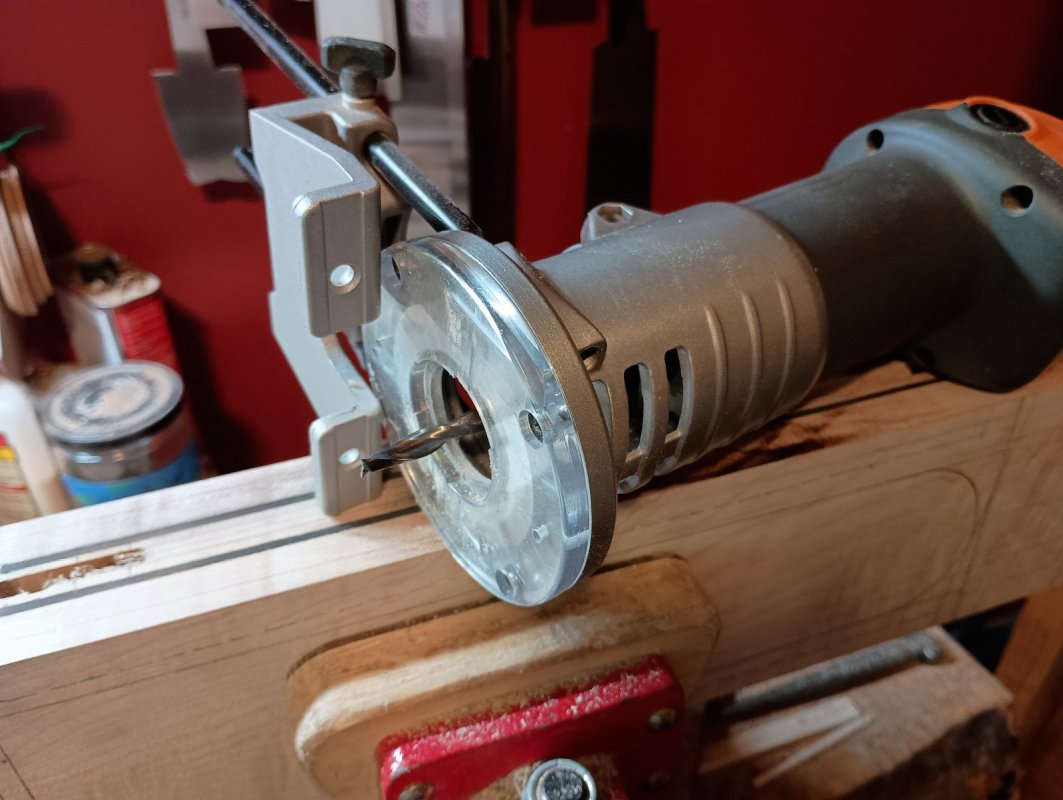

After getting everything setup to rout the channel for the truss rod, centered carefully with the 1/4" bit, only taking a 1/4" bite for the first pass, I started in. Everything's going smoothly then it starts to get harder and harder and it starts to push against the side guide. I shut it off and the horrible truth is revealed.

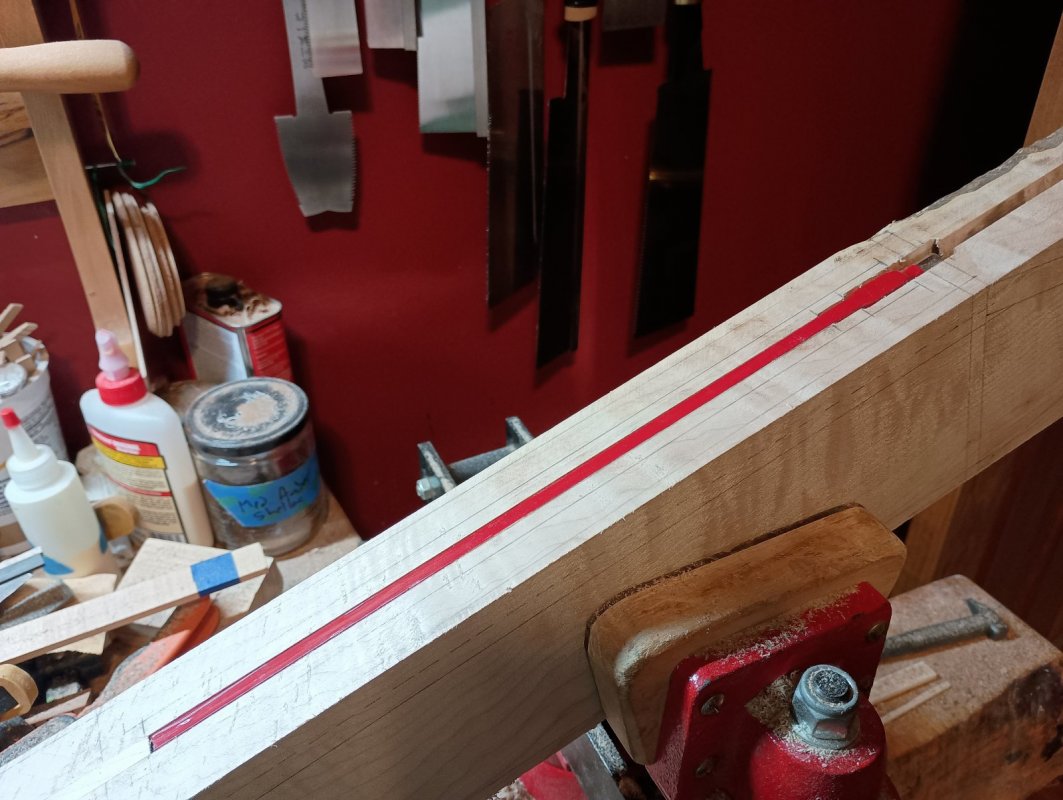

Ok, I can inlay where it got pushed off the line and reroute.

Then I noticed the bit.

Unbeknownst to me, the reason it got difficult was that the bit had been working it's way down, despite being wrenched in. It's still tight in the collet, just more than 1/2" further out than it should be. Below where the neck would be carved.

After ruminating overnight on the best course of action, I decided to flip the neck blank over and start again. Another option would be to cut through where the truss rod goes and make it a laminated neck. Back to the drawing board.

I think I can cut the carbon fiber reinforcements out and reuse them.

But I may do the truss rod channel at the table saw. It means filling in where the channel should stop, since the table saw us a through cut, but it's safer.