AcornHouse

Venerated Member

So, what's going on with Thistle I hear you ask?

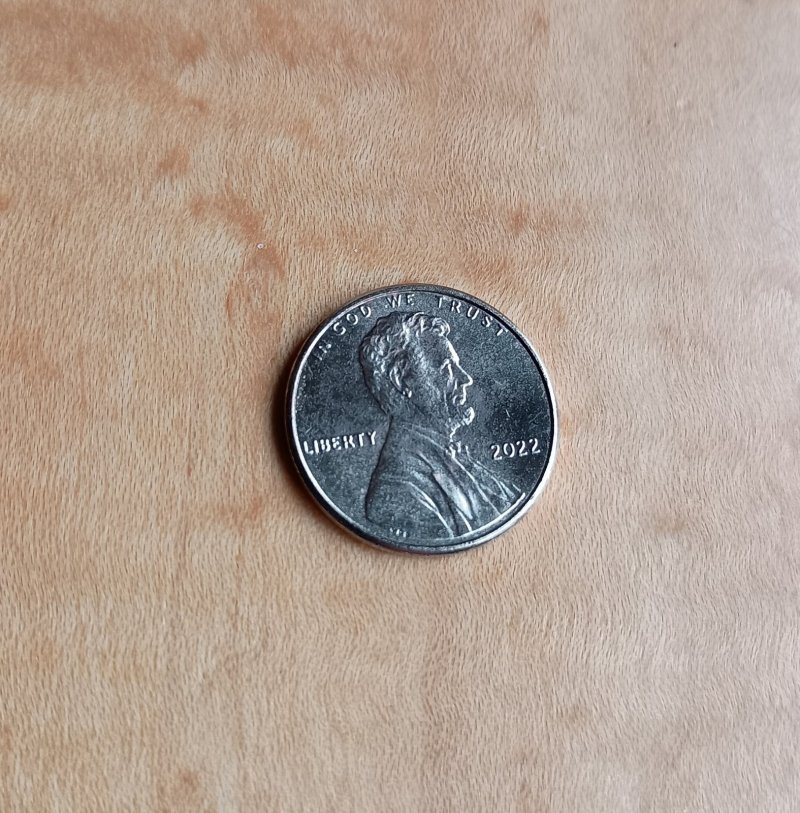

I think I have enough shellac on at this point. Now it gets to sit for a few days to let the shellac cure and shrink and the oil to completely rise to the surface as much as it can. Then I'll do the spiriting off process, using mostly alcohol, to draw out the oil and bring up the gloss.

I think I have enough shellac on at this point. Now it gets to sit for a few days to let the shellac cure and shrink and the oil to completely rise to the surface as much as it can. Then I'll do the spiriting off process, using mostly alcohol, to draw out the oil and bring up the gloss.