SFIV1967

Venerated Member

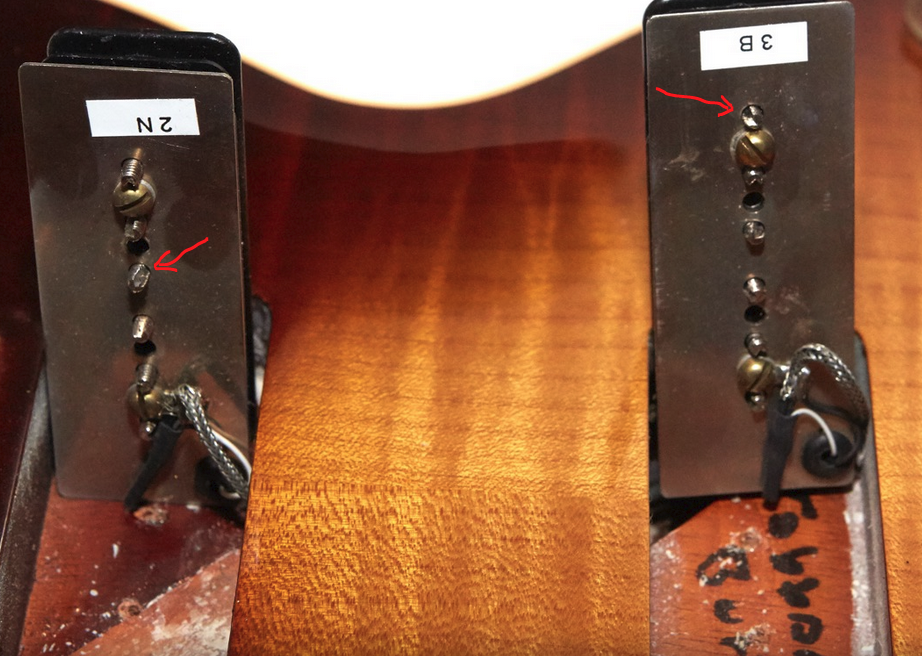

@beinhard posted those pictures of the Chris Fleming guitar's P90 pickups and I imediatelly noticed the modified pole screws.

What does that modification do ?I guess Chris Fleming had a reason for this. Anybody has an idea? Just curious.

Ralf

What does that modification do ?

Ralf

Last edited: