BradHK

Senior Member

- Joined

- Jul 1, 2014

- Messages

- 1,084

- Reaction score

- 2,806

In January I purchased a 1954 Guild M-75 that needed a TON of work. The guitar was discussed here (if I can get the link to work): https://letstalkguild.com/ltg/index.php?threads/project-vintage-m-75-on-ebay.210586/

Based upon the photos and answers from the seller (it was an estate sale) the back had separated from the front near the tailpiece probably due to water or high moisture exposure, it was missing the bridge, tuners and some other small pieces, it included the original case (that had some water damage to the lower edge). However, it was not modified and had its original finish and electronics. I rolled the dice and took a gamble.

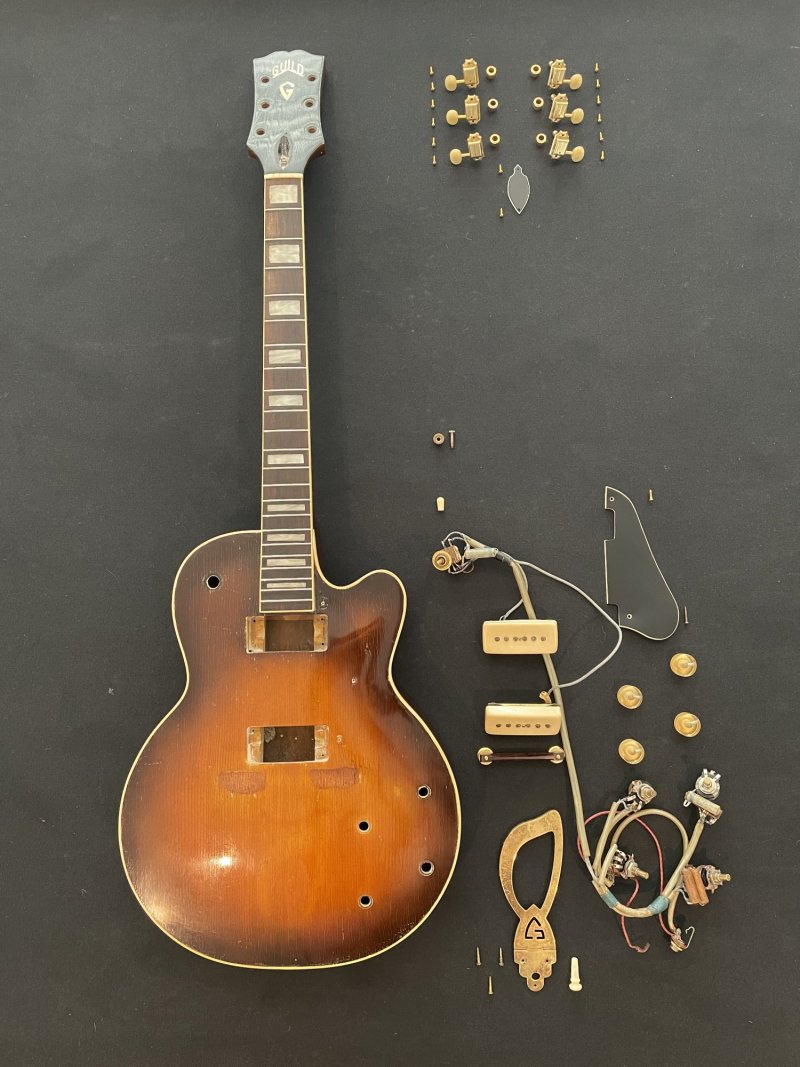

When the guitar arrived I was pleasantly surprised that there were no additional “surprises”. The neck was perfectly straight, the original frets looked beautiful and the electronics were 100% original. I completely disassembled the guitar, inspected everything, and started to make a list of what needed to be done to get it back up and running. It needed some structural work done where the glue had failed and it also needed new body binding. I was going to perform this work myself then came to my senses and gave Tom Jacobs a call. After photos were sent and some discussions were held the guitar body was packed up and sent to Tom. The eBay seller had what appeared to be the original Guild Kluson no-line tuners (they were not on the guitar but were in the estate from the same person who had this guitar). I purchased those and some other small bits like a catalin switch tip from a gentleman that machines catalin switch tips from old Chinese catalin dominos. Everything has now been gone through and is ready to drop back into the body.

I just received a call this morning from Delyne at Tom’s shop and the body is ready and is being shipped back today! I will post more updates as it is put back together but I am so excited to have the guitar on its way back to me I just had to share. Here are some “before“ photos:

Based upon the photos and answers from the seller (it was an estate sale) the back had separated from the front near the tailpiece probably due to water or high moisture exposure, it was missing the bridge, tuners and some other small pieces, it included the original case (that had some water damage to the lower edge). However, it was not modified and had its original finish and electronics. I rolled the dice and took a gamble.

When the guitar arrived I was pleasantly surprised that there were no additional “surprises”. The neck was perfectly straight, the original frets looked beautiful and the electronics were 100% original. I completely disassembled the guitar, inspected everything, and started to make a list of what needed to be done to get it back up and running. It needed some structural work done where the glue had failed and it also needed new body binding. I was going to perform this work myself then came to my senses and gave Tom Jacobs a call. After photos were sent and some discussions were held the guitar body was packed up and sent to Tom. The eBay seller had what appeared to be the original Guild Kluson no-line tuners (they were not on the guitar but were in the estate from the same person who had this guitar). I purchased those and some other small bits like a catalin switch tip from a gentleman that machines catalin switch tips from old Chinese catalin dominos. Everything has now been gone through and is ready to drop back into the body.

I just received a call this morning from Delyne at Tom’s shop and the body is ready and is being shipped back today! I will post more updates as it is put back together but I am so excited to have the guitar on its way back to me I just had to share. Here are some “before“ photos: