- Joined

- Dec 21, 2022

- Messages

- 5

- Reaction score

- 2

- Guild Total

- 1

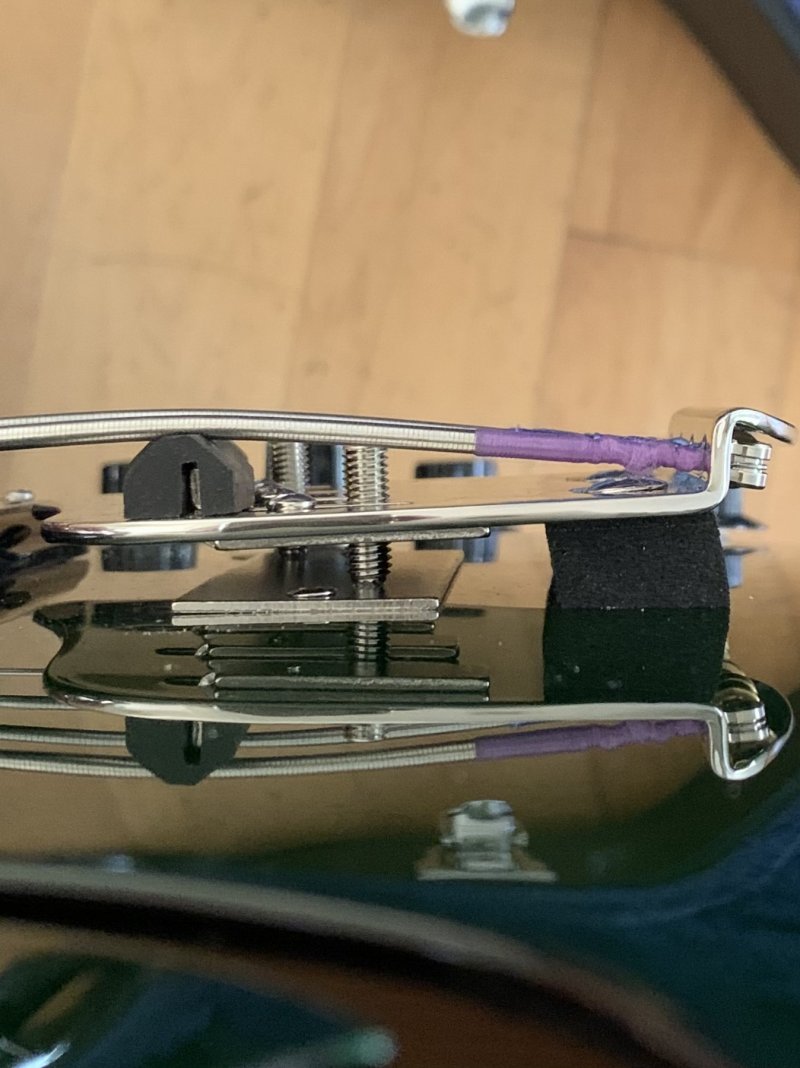

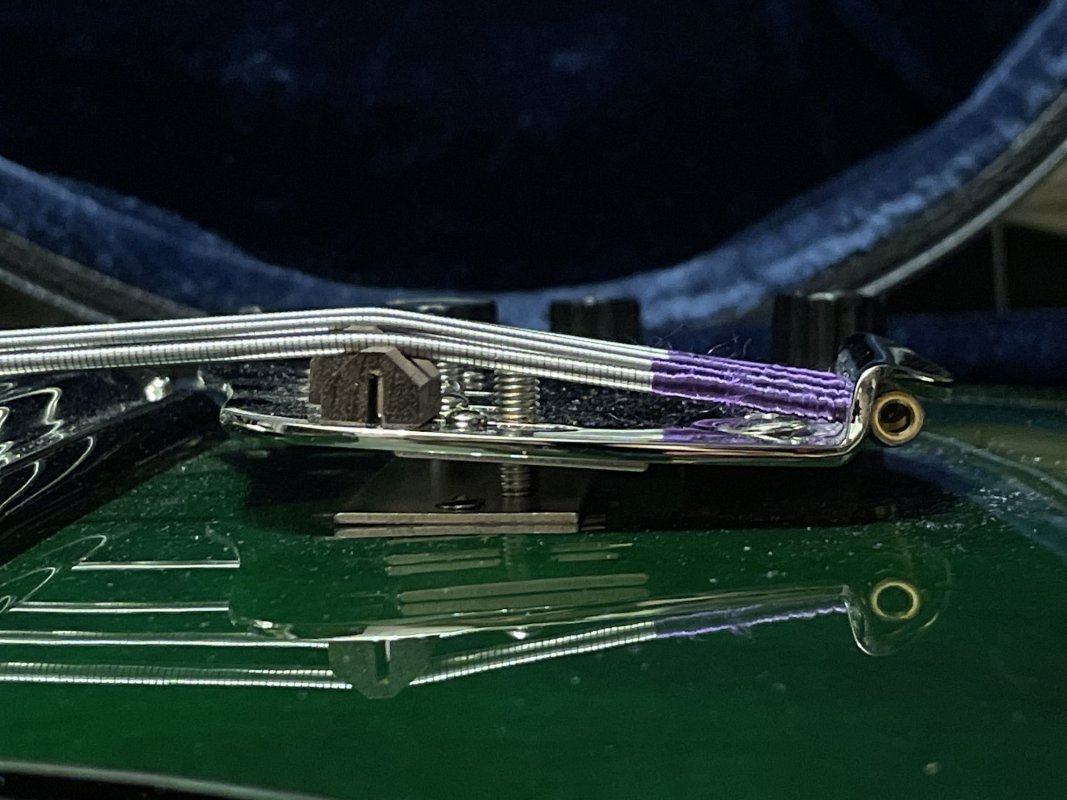

Purchased new this week. I’m still deciding whether or not I’ll be keeping it or sending it back. With that in mind has anybody else had an issue with the E string slipping out of the rosewood saddle? I’d imagine filing the saddle groove deeper will secure the string better. But I’m not totally convinced. I don’t want to alter the bass unless I know it will work. I palm mute at the bridge and often dig in quite hard with a pick. So far I’m experimenting with thinner strings and this 100 gauge E gauge seems to slip even worse. Here’s two shots the first is where the string wants to rest naturally and the other with me physically pulling the string over the saddle. Love to hear if people are coming across this issue and how they’re dealing with it. Cheers!