lungimsam

Senior Member

- Joined

- Oct 1, 2011

- Messages

- 2,628

- Reaction score

- 1,693

- Guild Total

- 2

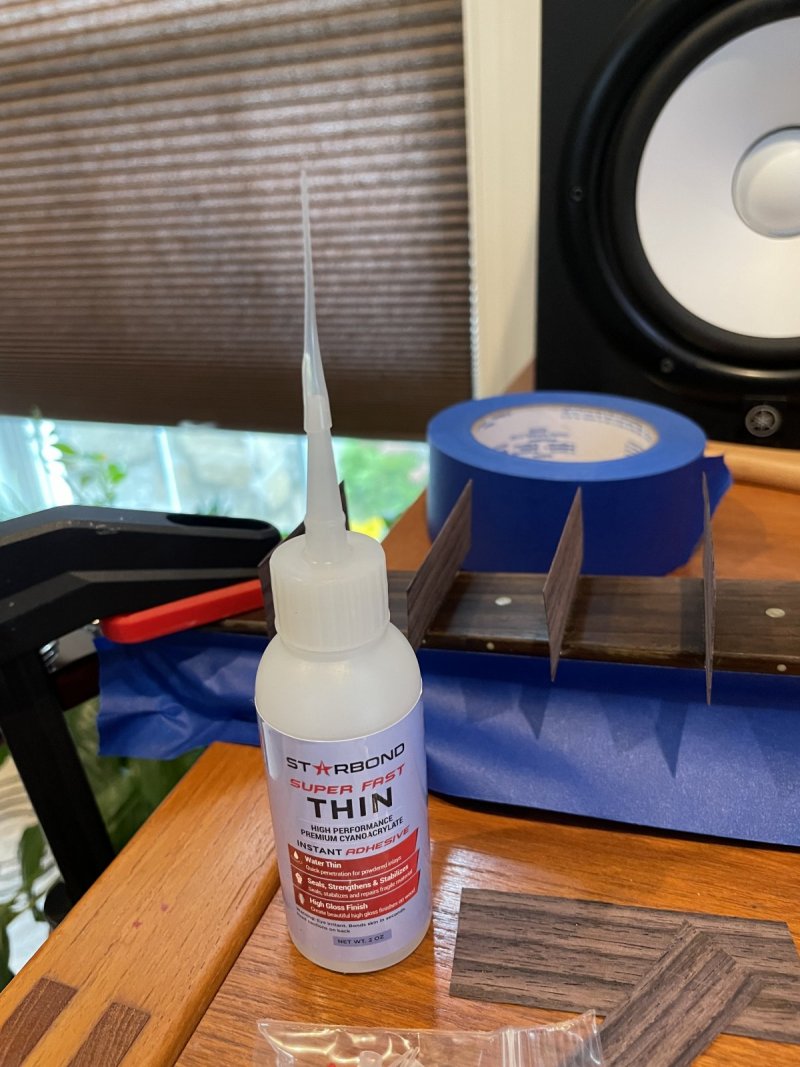

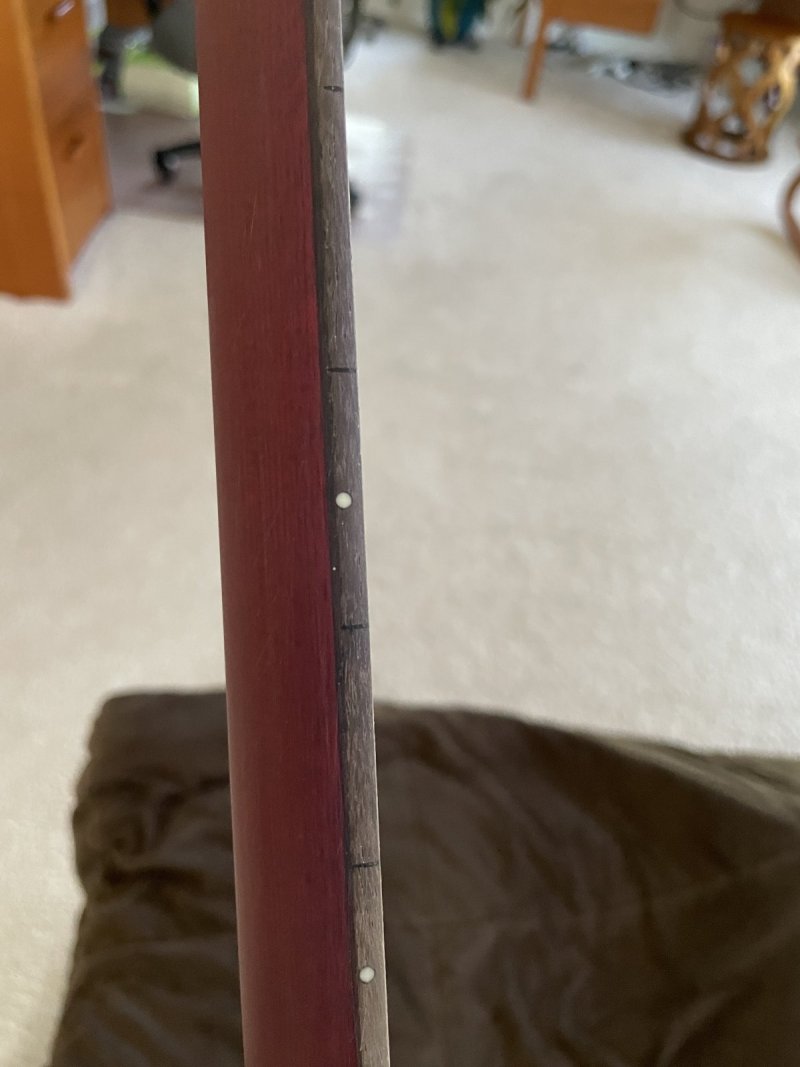

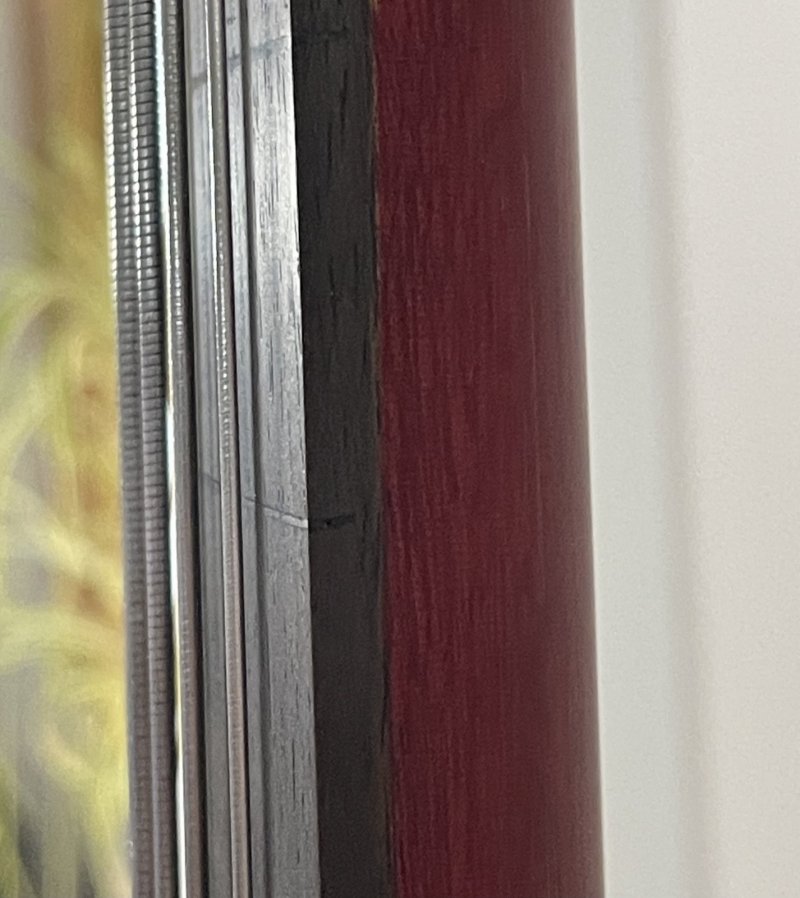

Started with these nippers I got. They are utterly flat on their face so they serve the dual purpose of pinching out the frets while I push down on the fretboard to reduce wood tear out. Worked great. Clean removal and no tear out and did not have to heat or water the frets before hand. The handy fret saw easily fit right in the slots and cleaned them out. The ends of the fret slots were covered in gloss poly finish after fret removal still but the fret saw notched thru it without gloss finish tear out. Next is gluing in the veneers. Notice I had my bass on the desk, truss rod in neutral, and a rice bag on the body and a vice on the neck to bend the neck back slightly to help with opening the fret slots to make it easier to remove the frets. Praise the Lord everything has been so easy. Note the finish fog on the edge of the fingerboard from fret 1-5. The bass came that way when I bought it. I might sand the finish off the fingerboard sides when this is done to see if it’s finish fog or the fingerboard color. All this took about 35 minutes.

Nippers:

Fret slot saw:

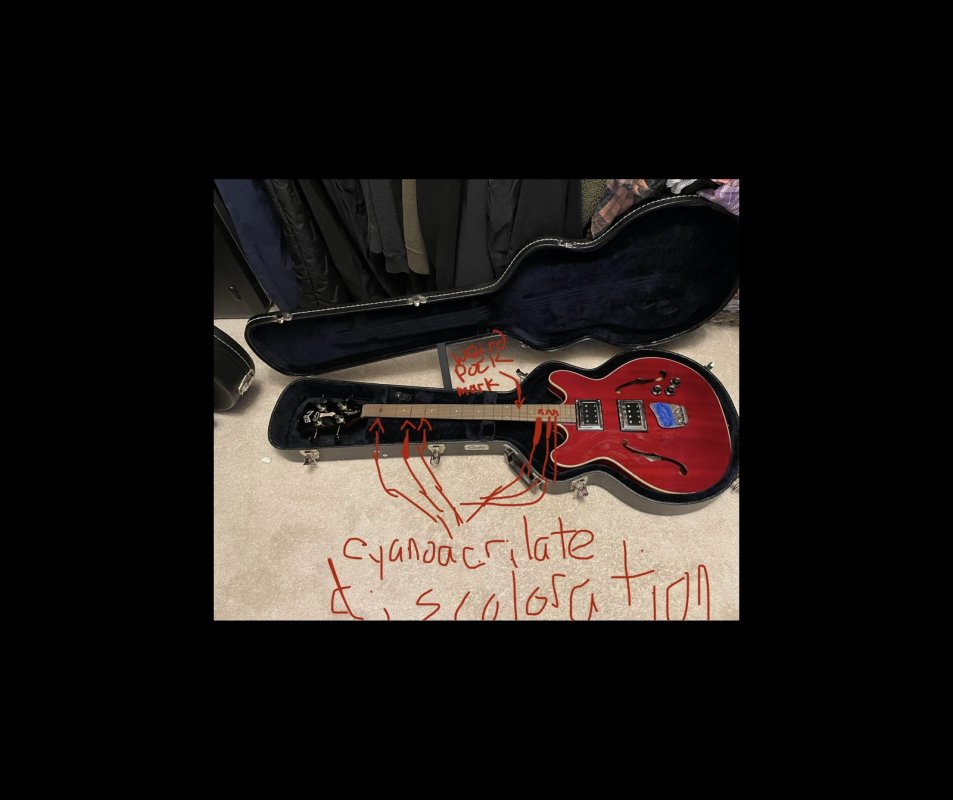

This is my 2013 Starfire I that I added a neck pickup to a while back.

Nippers:

MX0361D 6-inch Fret Wire Cutter End Nippers Guitar Fret Wire End Cutting Pliers Luthier Tool Nipper Puller Pliers String Scissors End Nip Trimmer Brand: ERYUE

Fret slot saw:

Guitars Frets Knife, Lightweight Convenient Guitar Slot Saw Blade for Music Instrument for Cleaning(M02835) Brand: Shanrya

This is my 2013 Starfire I that I added a neck pickup to a while back.

Attachments

Last edited: