You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Handmade

- Thread starter GGJaguar

- Start date

Many of the parts can be perfectly replicated by machines.

Yeah, but there's just something about an actual hand built guitar made w/o the benefits/or detriments of a machine that just does it for me. My Custom Builder, Richie Crowder, is a one man show and pours his heart into every guitar he produces. That's worth something to me.Many of the parts can be perfectly replicated by machines.

fronobulax

Bassist, GAD and the Hot Mess Mods

- Joined

- May 3, 2007

- Messages

- 24,772

- Reaction score

- 8,900

- Location

- Central Virginia, USA

- Guild Total

- 5

At New Hartford the belief was that there were things that machines could do better than people and a belief that for a manufacturing facility, consistency was worth striving for. So the factory (and not just the Guild portion) was looking for ways to improve. I seem to recall that using a CNC machine to cut braces had a huge impact because the bracing pieces were more consistent and thus easier to "install".

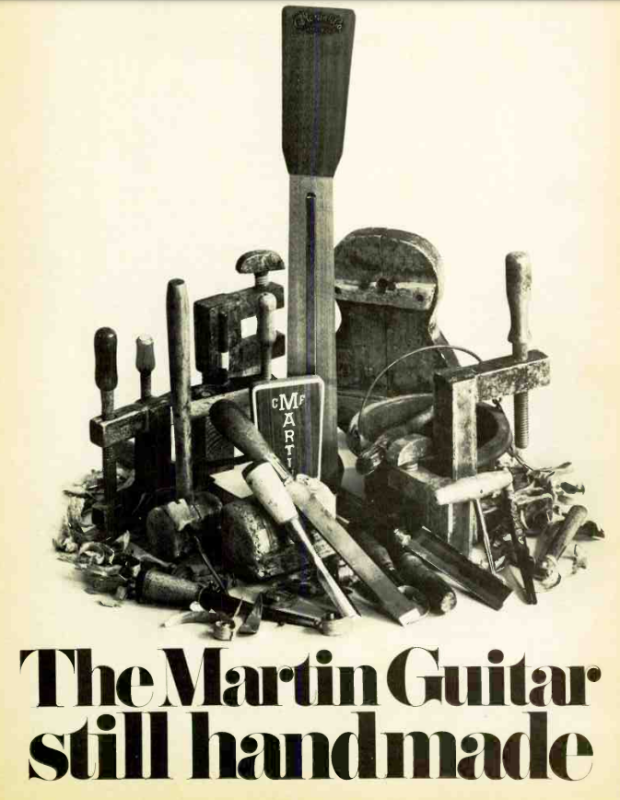

I also note the mystique about "handmade". What does it really mean? Is it still handmade if the builder uses a power saw or starts from a pre-fabricated part? Maybe the standard is that the only tools used are powered by human muscle? There are people who are saddened when a powered drill is used.

I think I am less interested in "handmade" for some definition of "handmade" as I am in the number of people who worked on it. I will pay for an instrument that was "made" by a single person who had a vision and used parts, tools and techniques to achieve that vison. My pride is that Chris made the mandolin (not mine) or Darryl made the bass (mine) and not how they did it.

I also note the mystique about "handmade". What does it really mean? Is it still handmade if the builder uses a power saw or starts from a pre-fabricated part? Maybe the standard is that the only tools used are powered by human muscle? There are people who are saddened when a powered drill is used.

I think I am less interested in "handmade" for some definition of "handmade" as I am in the number of people who worked on it. I will pay for an instrument that was "made" by a single person who had a vision and used parts, tools and techniques to achieve that vison. My pride is that Chris made the mandolin (not mine) or Darryl made the bass (mine) and not how they did it.

Mayve "hand assembled. would be a better term."

Westerly Wood

Venerated Member

- Joined

- Mar 21, 2007

- Messages

- 13,438

- Reaction score

- 6,668

- Guild Total

- 2

I always like to think one of the 3 amigos had a hand on the BR, at some point in its construction run. NO doubt, this a pipe dream...maybe even just to move it out of the way as they were working on a more expensive, unique Guild acoustic...

merlin6666

Senior Member

Yes I think Ovation in New Hartford was first to introduce CNC and bolt on necks to guitar manufacturing. On the other hand, they discontinued Adamas 1687 in the late 90s because it required much more manual labour than any other guitar and became way too expensive to make (much more than they were sold for).At New Hartford the belief was that there were things that machines could do better than people and a belief that for a manufacturing facility, consistency was worth striving for. So the factory (and not just the Guild portion) was looking for ways to improve. I seem to recall that using a CNC machine to cut braces had a huge impact because the bracing pieces were more consistent and thus easier to "install".

I also note the mystique about "handmade". What does it really mean? Is it still handmade if the builder uses a power saw or starts from a pre-fabricated part? Maybe the standard is that the only tools used are powered by human muscle? There are people who are saddened when a powered drill is used.

I think I am less interested in "handmade" for some definition of "handmade" as I am in the number of people who worked on it. I will pay for an instrument that was "made" by a single person who had a vision and used parts, tools and techniques to achieve that vison. My pride is that Chris made the mandolin (not mine) or Darryl made the bass (mine) and not how they did it.

I am always sceptical of Chinese companies that boldly state their instruments are "hand crafted" as this gives me visions of enslaved monkeys doing menial tasks.

- Joined

- Feb 11, 2009

- Messages

- 23,167

- Reaction score

- 18,896

- Location

- NJ (The nice part)

- Guild Total

- 112

After conversing with Bob Benedetto my opinion of build techniques evolved. All of the Benedetto Guild tops and backs were cut by a machine that copied an original that was carved by Bob. I’m sure someone will be along with the name if that machine which escapes me at the moment.

Then a luthier trained by Bob finish-carved those machine-cut pieces to perfection. At the end Bob inspected them and signed the sticker.

“Hand made” is a useless term IMO, and is nothing more than a marketing term. Look at the @AcornHouse build thread. That’s a hand made guitar! If you gave me the same tools and the same workshop and I hand-made a guitar, I guarantee you that it would not have the same wow-factor as his remarkable build. It might even be dangerous.

Then a luthier trained by Bob finish-carved those machine-cut pieces to perfection. At the end Bob inspected them and signed the sticker.

“Hand made” is a useless term IMO, and is nothing more than a marketing term. Look at the @AcornHouse build thread. That’s a hand made guitar! If you gave me the same tools and the same workshop and I hand-made a guitar, I guarantee you that it would not have the same wow-factor as his remarkable build. It might even be dangerous.

GGJaguar

Reverential Member

I'd end up with a big pile of sawdust and splintered wood. I wouldn't even make it to the assembly phase let alone the finishing phase.If you gave me the same tools and the same workshop and I hand-made a guitar

Hey, Merlin,Yes I think Ovation in New Hartford was first to introduce CNC and bolt on necks to guitar manufacturing. . . .

I'm pretty sure Bob Taylor would take issue with that.

Westerly Wood

Venerated Member

- Joined

- Mar 21, 2007

- Messages

- 13,438

- Reaction score

- 6,668

- Guild Total

- 2

fronobulax said:Hey, Merlin,

I'm pretty sure Bob Taylor would take issue with that..

I'm not sure I follow your analogy since the federal Income tax goes back to Abraham Lincoln. Are you suggesting Taylor revitalized someone else's idea

Last edited:

merlin6666

Senior Member

Taylor did that roughly 20 years after Ovation!Hey, Merlin,

I'm pretty sure Bob Taylor would take issue with that..

Westerly Wood

Venerated Member

- Joined

- Mar 21, 2007

- Messages

- 13,438

- Reaction score

- 6,668

- Guild Total

- 2

kidding, I don't know, just thought my bit was funny...Taylor did that roughly 20 years after Ovation!

Westerly Wood

Venerated Member

- Joined

- Mar 21, 2007

- Messages

- 13,438

- Reaction score

- 6,668

- Guild Total

- 2

I know on the AGF back in day, the pre-NT neck Taylors were the most sought after. I don't know if that is "bolt-on", but I bought a 1996 712 and was really psyched cause it had a pre-NT neck. That was a great guitar.. Well, I saw something where he claimed to be the first with CNC machines, merlin. I don't think he claimed anything regarding bolt-ons as that clearly pre-dated him.

If you can find Lemon Grove Taylors, those are really special.

AcornHouse

Venerated Member

Pantograph router, most likely.After conversing with Bob Benedetto my opinion of build techniques evolved. All of the Benedetto Guild tops and backs were cut by a machine that copied an original that was carved by Bob. I’m sure someone will be along with the name if that machine which escapes me at the moment.

I’m still learning too. It’s all about building skills. My builds have improved with each one, but still could be better.Then a luthier trained by Bob finish-carved those machine-cut pieces to perfection. At the end Bob inspected them and signed the sticker.

“Hand made” is a useless term IMO, and is nothing more than a marketing term. Look at the @AcornHouse build thread. That’s a hand made guitar! If you gave me the same tools and the same workshop and I hand-made a guitar, I guarantee you that it would not have the same wow-factor as his remarkable build. It might even be dangerous.

- Joined

- Feb 11, 2009

- Messages

- 23,167

- Reaction score

- 18,896

- Location

- NJ (The nice part)

- Guild Total

- 112

- Joined

- Feb 11, 2009

- Messages

- 23,167

- Reaction score

- 18,896

- Location

- NJ (The nice part)

- Guild Total

- 112

There it is! I can never remember that word.Pantograph router, most likely.

fronobulax

Bassist, GAD and the Hot Mess Mods

- Joined

- May 3, 2007

- Messages

- 24,772

- Reaction score

- 8,900

- Location

- Central Virginia, USA

- Guild Total

- 5

Bob Taylor is to CNC as Woodrow Wilson is to Income Tax.

I'm not sure I follow your analogy since the federal Income tax goes back to Abraham Lincoln. Are you suggesting Taylor revitalized someone else's idea?

Westerly Wood

Venerated Member

- Joined

- Mar 21, 2007

- Messages

- 13,438

- Reaction score

- 6,668

- Guild Total

- 2

Thanks Frono for this...I am now changing my intent to what you suggest here, it sounds way more visionary than my original reply.I'm not sure I follow your analogy since the federal Income tax goes back to Abraham Lincoln. Are you suggesting Taylor revitalized someone else's idea