AcornHouse

Venerated Member

I thought I should start a separate thread with the uke build to keep a little separation. I'll do the same with the slope shoulder dread. This will be a soprano ukulele that a former student is having built for his wife who is a music teacher in the Nashville area (and is ALSO a former student.) This one has a hard deadline for her birthday on April.

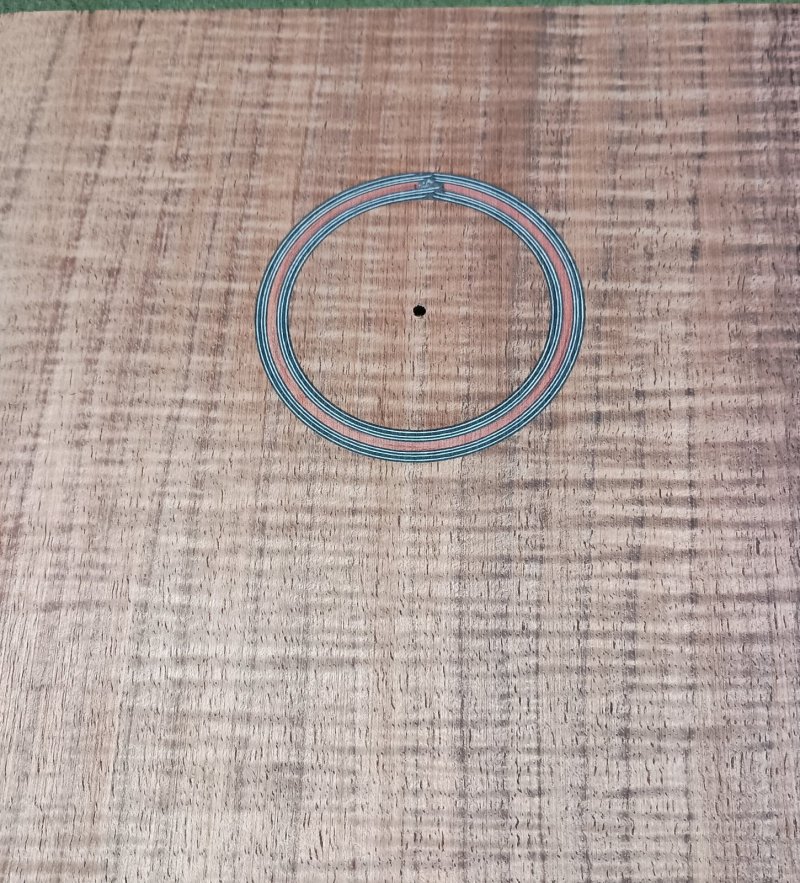

I took advantage of the rare sunny day with temps around 50⁰ to go out to the workshop and mill some bloodwood binding strips and get the pattern finalized in plywood.

Nica doing quality control, of course.

I took advantage of the rare sunny day with temps around 50⁰ to go out to the workshop and mill some bloodwood binding strips and get the pattern finalized in plywood.

Nica doing quality control, of course.