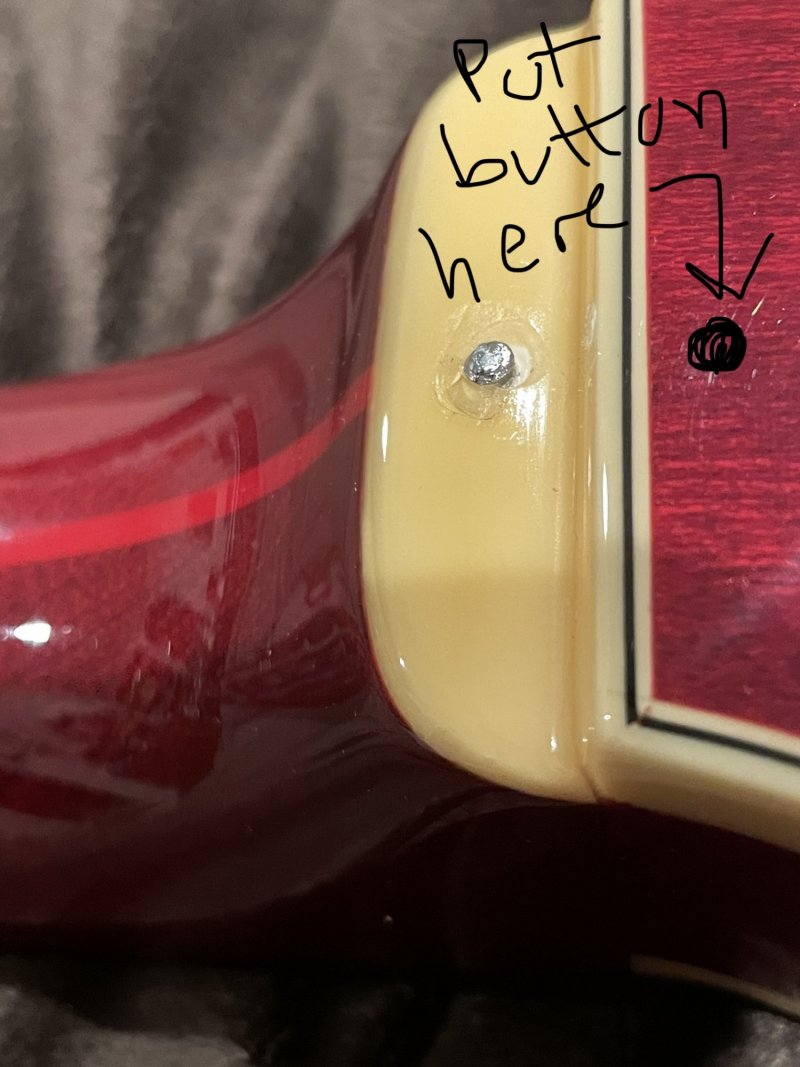

Upon further inspection, the binding damage around the screw hole (you can see in pic) is cracked up so much already and will not provide a stable footing for the new strap button even if I get the screw out. It may have been moving already, and I was unawares, and maybe led to the cracking and screw being so ready to snap, as it did.

Looks like the only 2 solutions to allow for a dependable footing for the button will be:

1. Use a screw extractor or cylinder type extractor, and then drill a dime sized hole thru the binding and wood (to completely remove the cracked up binding) and then dowel it perfectly and then sand it flush, which I would have to give to my luthier friend to do, cuz I don't think I have the tools to do such a precision match in dowel size, etc. I am also concerned since it is so cracked up already the drilling may tear out more of the binding, which becomes a whole bigger job to fix.

2. Or, I could just leave it as is and install the new strap button just behind it, on the body edge of the neck heel like Gibson does (pic below).