lungimsam

Senior Member

- Joined

- Oct 1, 2011

- Messages

- 2,608

- Reaction score

- 1,658

- Guild Total

- 2

The tape for the bridge ground wire is grounded already when it touches the bare wire end since that ground wire touches the back of a pot shell on its other end and then that goes to ground from that pot to output jack ground lug.

In theory yes all copper tape shielding needs continuity to the back of the pot all the other ground wires go to or to the ground lug of output jack somehow. Either by strips of tape that touches the back of a grounded pot shell or a wire jumper from the tape to the output jack ground lug.

However, I do have copper tape shielding covering my entire Ric bass pickguard back and control cavity, making a copper tape “box” that I never grounded or attached to a pot shell or output jack ground lug by jumper or any other means that I am aware of (unless the pot washers of the installed pots touching the copper shielding counts) and the bass is still dead quiet. So ymmv. Just be sure that you can trace with your finger a path to ground that leads eventually to the out put jack without going in a circle and coming back on itself making what is called a ground loop. So all shielding and ground wires must terminate on the same pot shell or on a point after the pot shell but on the same path to the output jack ground.

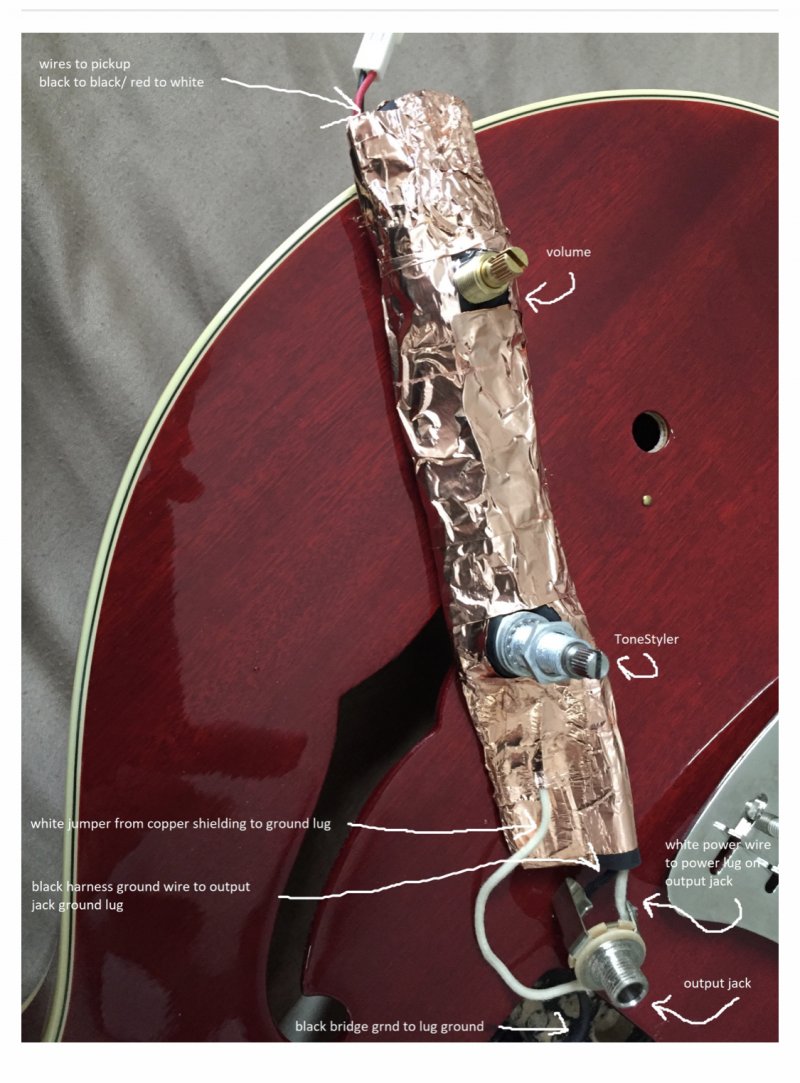

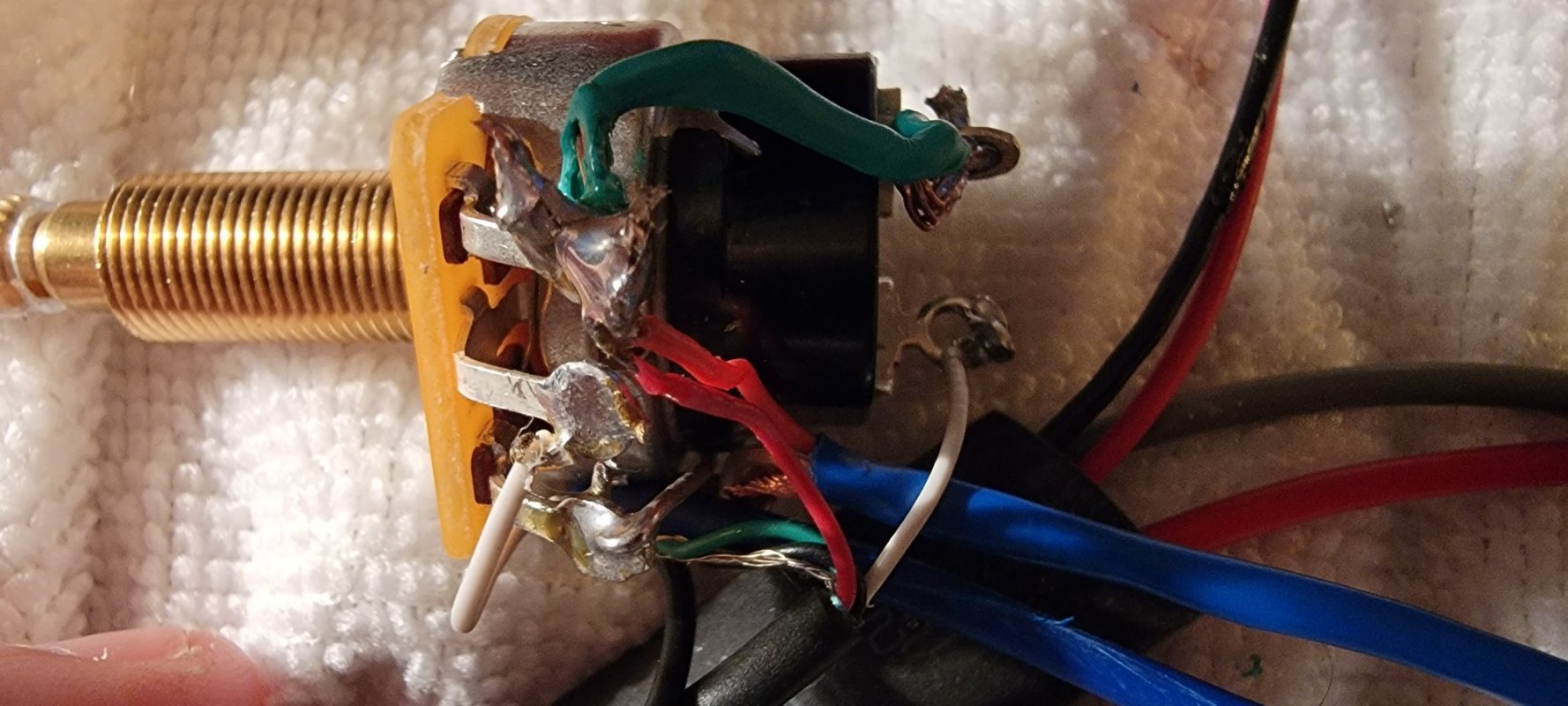

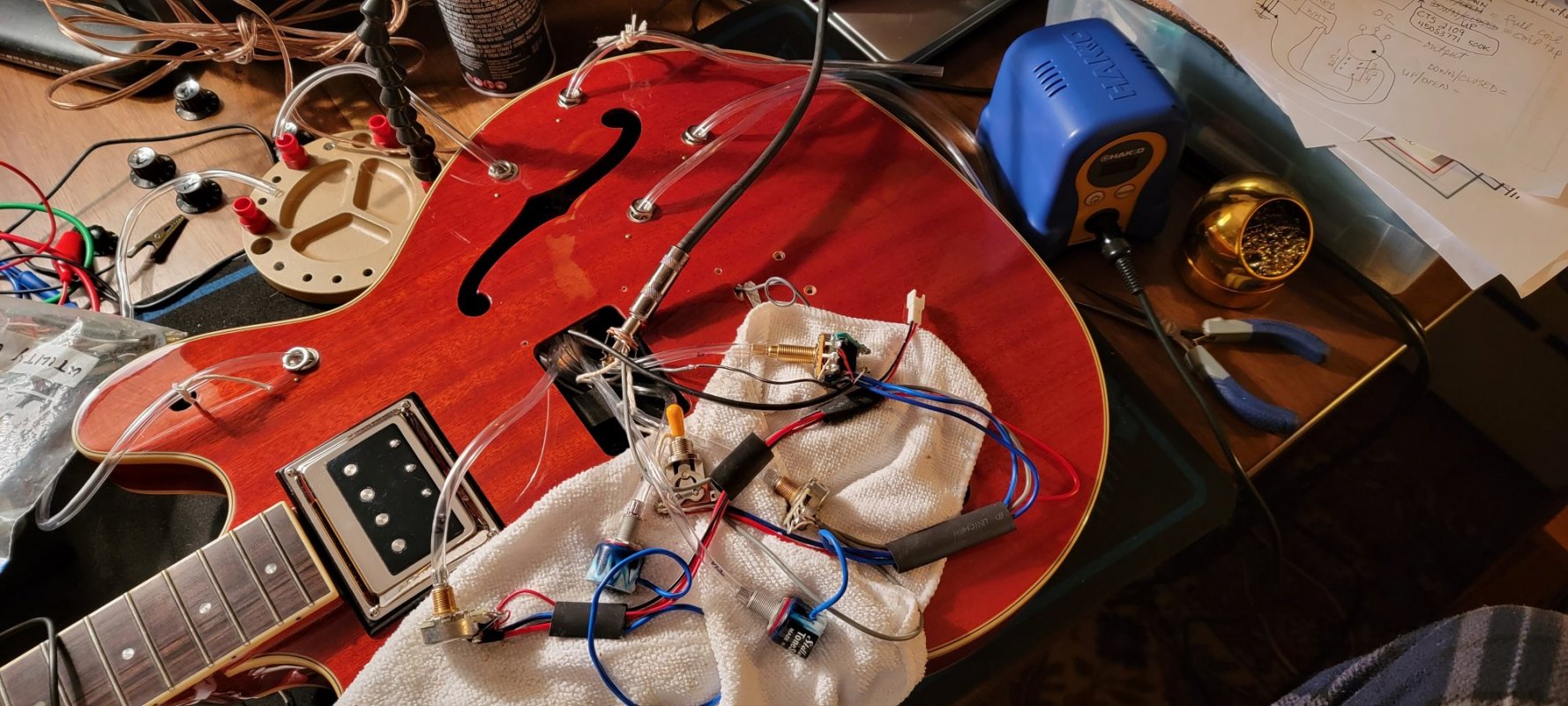

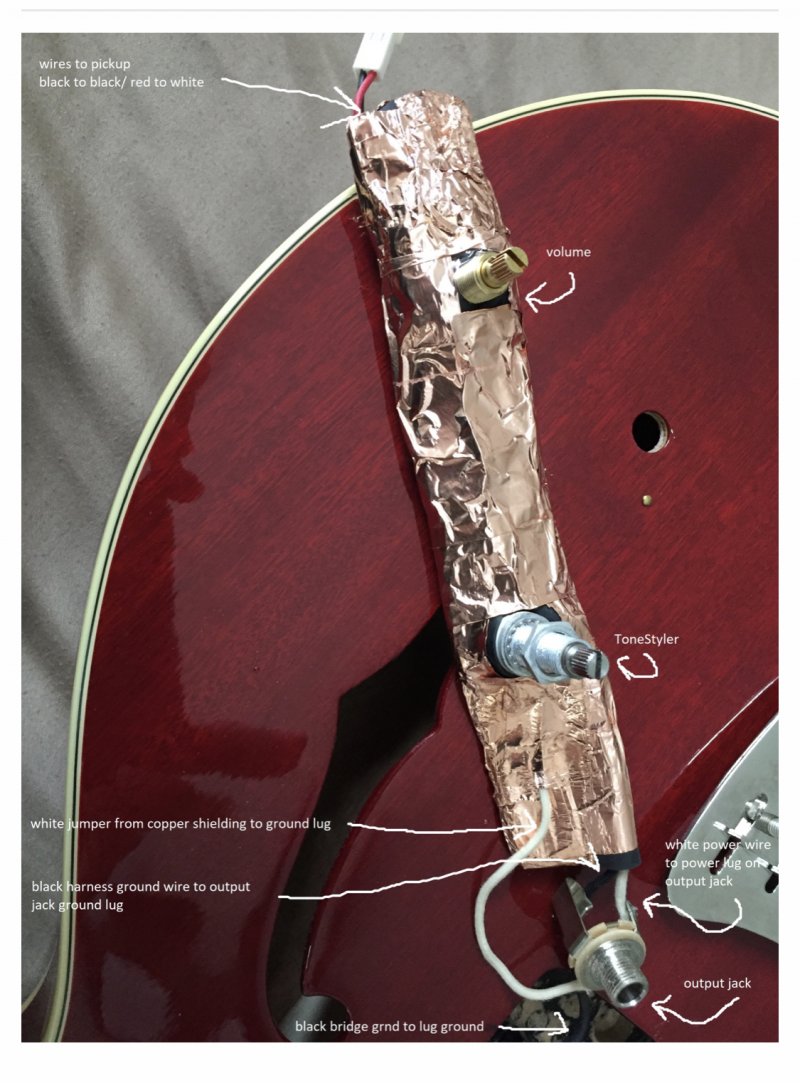

Completely shielding a harness inside a hollow or semi hollow body is a challenge. Wrapping the entire harness in butyl bicycle tire tubing and then taping over that with copper shielding tape and then jumpering the copper shielding packaging to output jack ground lug was done to great effect by myself on my Starfire I bass (as seen in my avatar pic) but I don’t know how well it could be pulled off on a Starfire II harness. My thread about shielding my NSStarfire I here: https://letstalkguild.com/ltg/index...shield-your-entire-ns-starfire-i-bass.199675/

I wish they would invent conductive shielding spray paint that could be blasted inside a semi hollow body and coat all interior walls then that could be jumpered to ground.

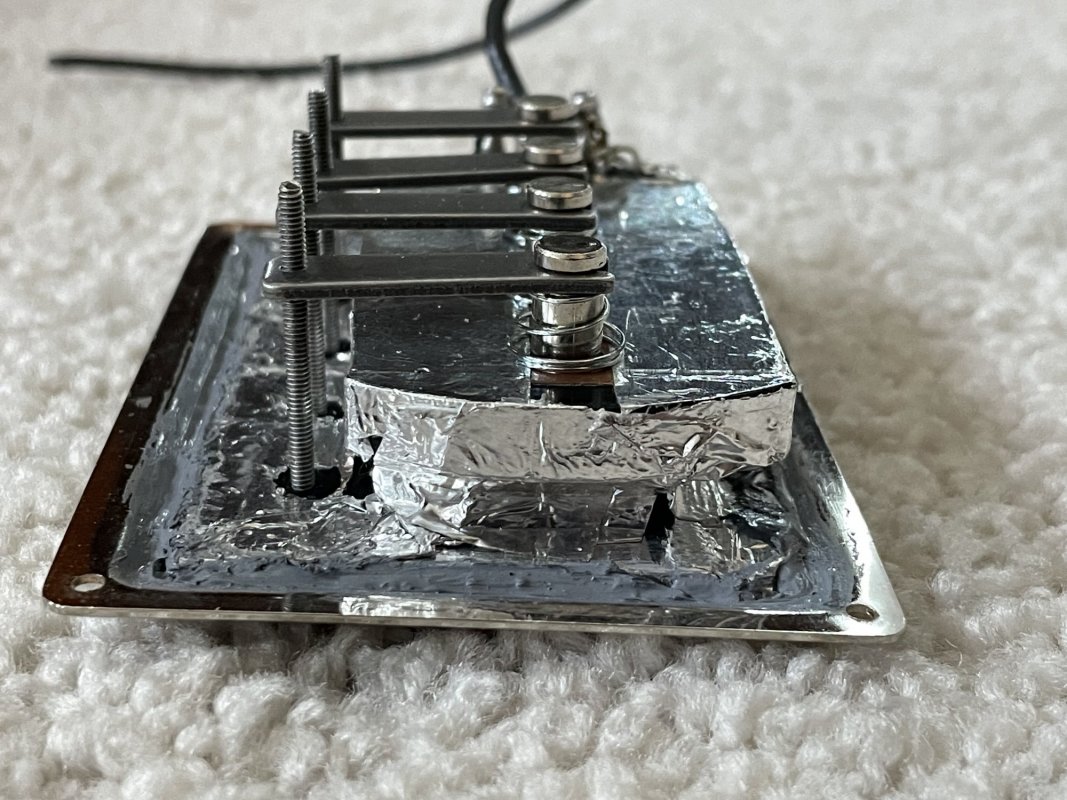

LTG member Default recently aluminum shielded taped my NS bisonic and that along with my shielded harness I did rendered the electronics dead silent in my Starfire I. Apparently, on a NS Bisonic anyway, the lamination that runs along the back of the pickup is grounded, so as long as you tape across that, all the tape will be grounded because the adhesive conducts too. Here are some pics of the shielded, two magnet magnet NS bisonic, as well as my coppershielded NSStarefireI harness before sliding that shielded package into the body thru the bridge pup cavity hole. Here's a pic of the Silversonic:

In theory yes all copper tape shielding needs continuity to the back of the pot all the other ground wires go to or to the ground lug of output jack somehow. Either by strips of tape that touches the back of a grounded pot shell or a wire jumper from the tape to the output jack ground lug.

However, I do have copper tape shielding covering my entire Ric bass pickguard back and control cavity, making a copper tape “box” that I never grounded or attached to a pot shell or output jack ground lug by jumper or any other means that I am aware of (unless the pot washers of the installed pots touching the copper shielding counts) and the bass is still dead quiet. So ymmv. Just be sure that you can trace with your finger a path to ground that leads eventually to the out put jack without going in a circle and coming back on itself making what is called a ground loop. So all shielding and ground wires must terminate on the same pot shell or on a point after the pot shell but on the same path to the output jack ground.

Completely shielding a harness inside a hollow or semi hollow body is a challenge. Wrapping the entire harness in butyl bicycle tire tubing and then taping over that with copper shielding tape and then jumpering the copper shielding packaging to output jack ground lug was done to great effect by myself on my Starfire I bass (as seen in my avatar pic) but I don’t know how well it could be pulled off on a Starfire II harness. My thread about shielding my NSStarfire I here: https://letstalkguild.com/ltg/index...shield-your-entire-ns-starfire-i-bass.199675/

I wish they would invent conductive shielding spray paint that could be blasted inside a semi hollow body and coat all interior walls then that could be jumpered to ground.

LTG member Default recently aluminum shielded taped my NS bisonic and that along with my shielded harness I did rendered the electronics dead silent in my Starfire I. Apparently, on a NS Bisonic anyway, the lamination that runs along the back of the pickup is grounded, so as long as you tape across that, all the tape will be grounded because the adhesive conducts too. Here are some pics of the shielded, two magnet magnet NS bisonic, as well as my coppershielded NSStarefireI harness before sliding that shielded package into the body thru the bridge pup cavity hole. Here's a pic of the Silversonic:

Attachments

-

DD62A675-FE5E-4CE8-9952-C2C830776815.jpeg519.9 KB · Views: 111

DD62A675-FE5E-4CE8-9952-C2C830776815.jpeg519.9 KB · Views: 111 -

507D416E-3F63-4ECD-A7BA-D25E87F5C258.jpeg618 KB · Views: 119

507D416E-3F63-4ECD-A7BA-D25E87F5C258.jpeg618 KB · Views: 119 -

6500535C-38C9-4CC8-8E76-EED5D06800B0.jpeg607.4 KB · Views: 117

6500535C-38C9-4CC8-8E76-EED5D06800B0.jpeg607.4 KB · Views: 117 -

45C71343-CD6A-4452-B386-7B8E4567A5FF.jpeg485 KB · Views: 119

45C71343-CD6A-4452-B386-7B8E4567A5FF.jpeg485 KB · Views: 119 -

F9D61719-C696-42D8-B503-BF4142FEC5E8.jpeg508.3 KB · Views: 117

F9D61719-C696-42D8-B503-BF4142FEC5E8.jpeg508.3 KB · Views: 117 -

EF976AD2-B230-4DE7-8039-E10E76ECB32F.jpeg466.5 KB · Views: 125

EF976AD2-B230-4DE7-8039-E10E76ECB32F.jpeg466.5 KB · Views: 125 -

B31D2CF2-F118-493F-BADF-18DF99DB3F73.jpeg1.5 MB · Views: 107

B31D2CF2-F118-493F-BADF-18DF99DB3F73.jpeg1.5 MB · Views: 107

Last edited: