Andrew79

Member

Earlier this year I bought a D-25M locally. It was installed with an L R Baggs M1 (I think?) pickup.

I have no use for it so I removed it and intend to sell it on Craigslist most likely.

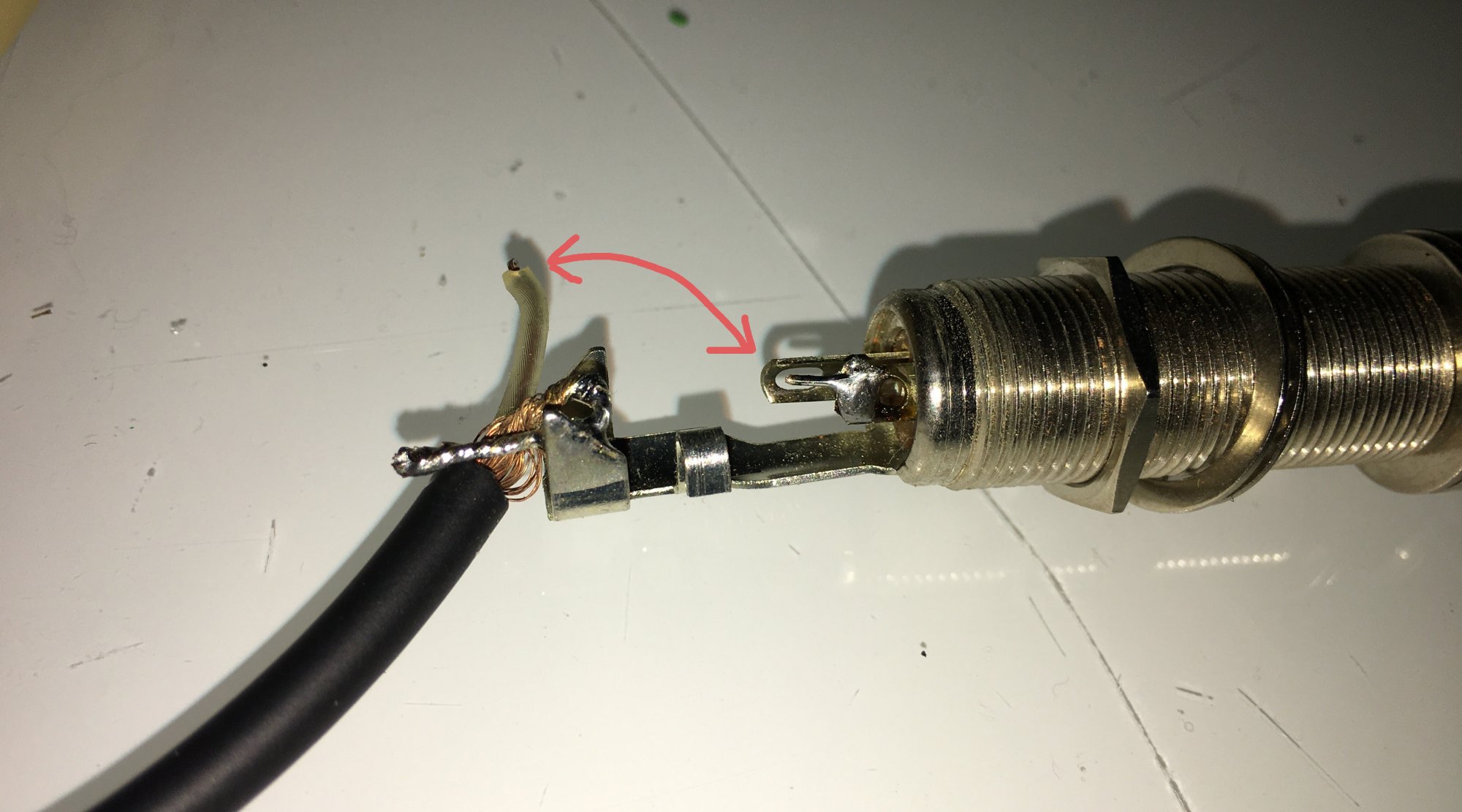

I know nothing about pickups but when inspecting it I noticed it looks like a wire has come loose from it's connection.

Looking at the picture, am I correct in thinking these two points should be soldered back together?

Many thanks for any advice you can provide

I have no use for it so I removed it and intend to sell it on Craigslist most likely.

I know nothing about pickups but when inspecting it I noticed it looks like a wire has come loose from it's connection.

Looking at the picture, am I correct in thinking these two points should be soldered back together?

Many thanks for any advice you can provide