JohnW63

Enlightened Member

"Wow. How did you come to know all that you know?"

One bit of knowledge at a time. The thing that separates some is how much they WANT to know in any given subject. It if really floats your boat, you can really go down a rabbit hole. My wife says I never go halfway in my hobbies. Lots of cameras and lenses in my closet. Too many guitars to play regularly in my computer/music room. The Mrs and I know way more about Triumph GT6s than we ever wanted to know, now.

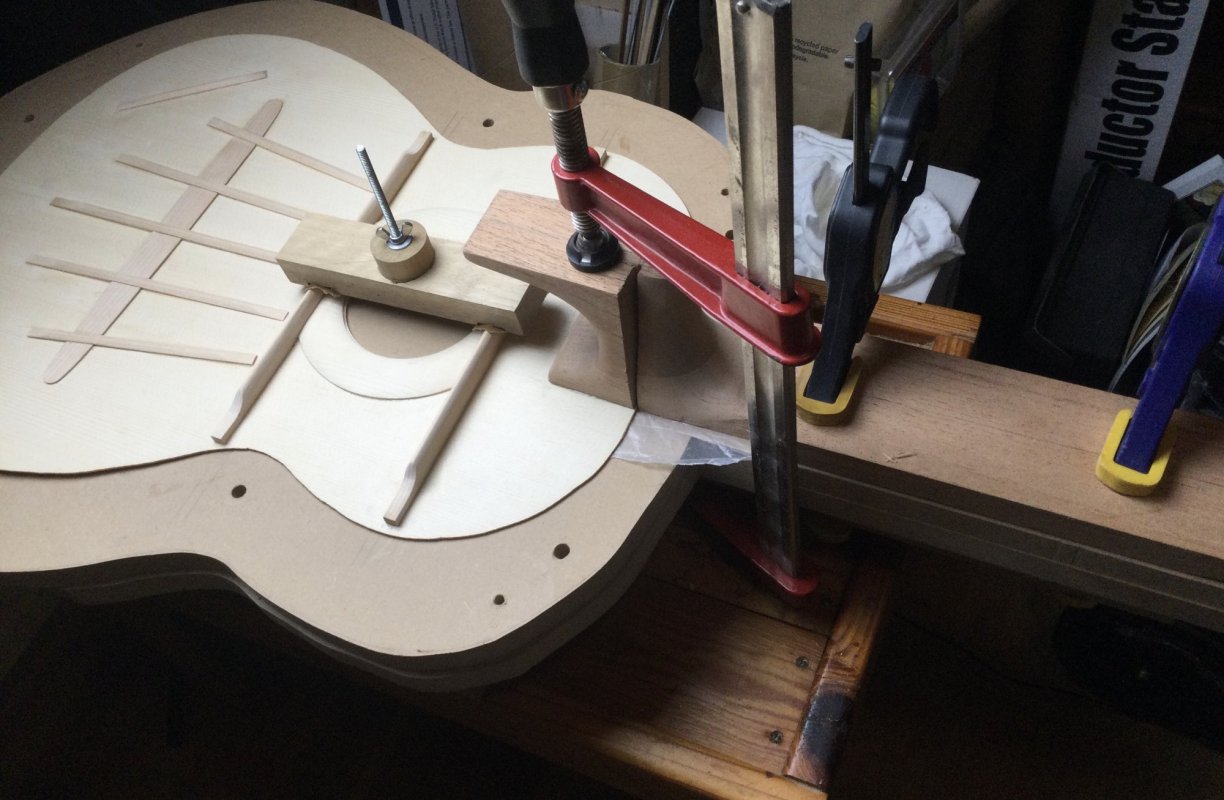

Chris as chosen to spend LOTS of time learning and building skills in guitar making. Thank goodness I don't have the shop space and time to go down that path!

One bit of knowledge at a time. The thing that separates some is how much they WANT to know in any given subject. It if really floats your boat, you can really go down a rabbit hole. My wife says I never go halfway in my hobbies. Lots of cameras and lenses in my closet. Too many guitars to play regularly in my computer/music room. The Mrs and I know way more about Triumph GT6s than we ever wanted to know, now.

Chris as chosen to spend LOTS of time learning and building skills in guitar making. Thank goodness I don't have the shop space and time to go down that path!