the sloppy slot is what irks me most about mine as well, it's like they built in the "wrong sized screwdriver slippage" splayed ends as an "authentic relic" feature! as i originally said though, at the time i was (and still am) just glad i found something that actually worked! if a reliable source of accurate screws is ever found there'll be a few happy guild owners worldwide i'm sure.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sold 3 pan head slot HB1 height adjustment screws #4-40 x 1 1/8"

- Thread starter SFIV1967

- Start date

Item has been sold

- Status

- Not open for further replies.

DThomasC

Senior Member

I'm going to make a wild assed guess and say that the old and new screws where manufactured by completely different processes. Maybe the old screws were made in something call a screw machine, where they were, well, machined from bar stock while the new ones are cold formed. That would mean that the old ones had their slot cut with some sort of cutting tool while the new ones have the entire head formed by mashing smaller gauge stock into the shape of the head. The result would be much less precise. I'm just guessing (aka making it all up.)

Whatever the real truth, you can bet that the new ones are different from the old ones for economic reasons.

Whatever the real truth, you can bet that the new ones are different from the old ones for economic reasons.

My vote is what ET said in previous post.

The Guilds of Grot

Enlightened Member

I think you've got it right on the head! (Pun intended!) I was going to post the exact same thing. To me it looks like the old screws slots are machined with a cutting mill so the sides are parallel. The new screws looks stamped where they would need some draft ( angled sides), for the punch to release.I'm going to make a wild assed guess and say that the old and new screws where manufactured by completely different processes. Maybe the old screws were made in something call a screw machine, where they were, well, machined from bar stock while the new ones are cold formed. That would mean that the old ones had their slot cut with some sort of cutting tool while the new ones have the entire head formed by mashing smaller gauge stock into the shape of the head. The result would be much less precise. I'm just guessing (aka making it all up.)

Whatever the real truth, you can bet that the new ones are different from the old ones for economic reasons.

davismanLV

Venerated Member

- Joined

- Mar 24, 2011

- Messages

- 19,344

- Reaction score

- 12,135

- Location

- U.S.A. : Nevada : Las Vegas

- Guild Total

- 2

Yeah if you tried to stamp that precise and perfect slot the screw's not gonna come out of the mold or whatever you call that. Now we can all rest easy about WHY.....

- Joined

- Feb 11, 2009

- Messages

- 22,991

- Reaction score

- 18,635

- Location

- NJ (The nice part)

- Guild Total

- 112

Looks like the guy I was talking to can't deliver after all. This is maddening.

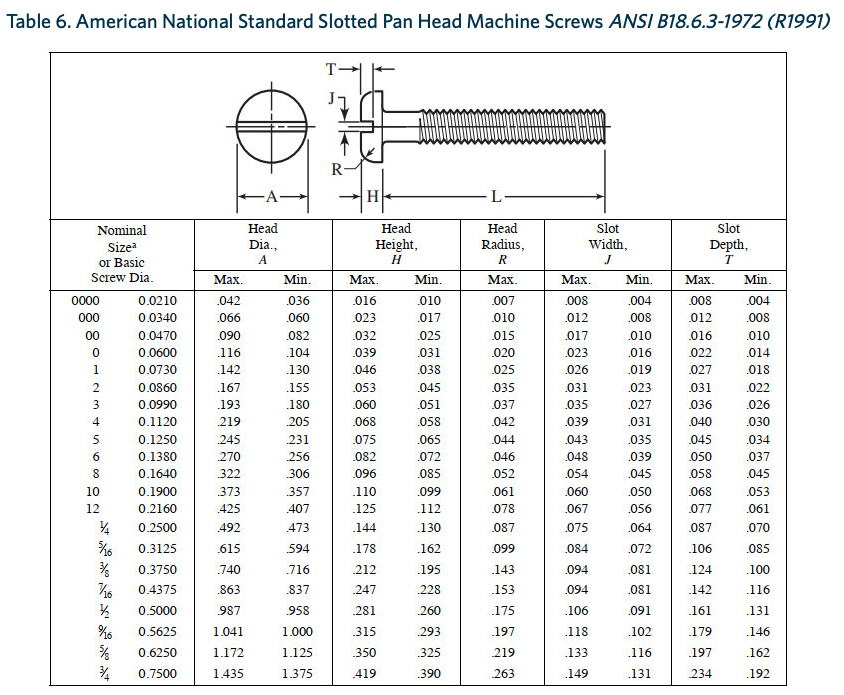

I've found that there is an ANSI standard for pan-head machine screws and it looks like this (from here):

I'm going to re-measure using 1/1000" and see if it fits in any of the standards. It wouldn't surprise me if it's a standard not seen much anymore, and it wouldn't surprise me if the above machining thoughts are true. What really bugs me is that the standard clearly shows a very flat head but none of the pan-heads I've been able to find look like that; they all look like fillister or binding heads to me.

I've found that there is an ANSI standard for pan-head machine screws and it looks like this (from here):

I'm going to re-measure using 1/1000" and see if it fits in any of the standards. It wouldn't surprise me if it's a standard not seen much anymore, and it wouldn't surprise me if the above machining thoughts are true. What really bugs me is that the standard clearly shows a very flat head but none of the pan-heads I've been able to find look like that; they all look like fillister or binding heads to me.

hansmoust

Enlightened Member

When I started out in the guitar repair business the main goal was to keep instruments in good working order; making sure that the instrument would do what it was designed for, or sometimes trying to improve on that. Originality was not really a big issue, not so much because it wasn’t important, but more so because of the limited availability of original parts; the fact that I’m located in the Netherlands also had a lot to do with that. The ‘vintage guitar’ phenomenon has changed all that, leading to situations in which totally unplayable, but original instruments are often more valuable than good workingman’s instruments that have a few parts changed.

Lucky for us we now have the ‘aftermarket’ replacement parts industry that helps us keep valuable instruments close to original, while we keep the original parts in a safe place.

Unfortunately there are no aftermarket screws available for ‘vintage’ Guild guitars, so as a repairman I would have no problem using a screw with the correct thread that would work as well as the original did. I could live with the ‘looks’ as long as it will keep the pickup in place; meanwhile one could search for something that looks closer to original.

For the HB-1 pickup Guild basically used two different height adjustment screws with a distinctive head shape.

Here are some photos that shows the two different styles.

Over the years there were several small variations in size, but you would only notice the difference by actually measuring them.

Sincerely,

Hans Moust

www.guitarsgalore.nl

Lucky for us we now have the ‘aftermarket’ replacement parts industry that helps us keep valuable instruments close to original, while we keep the original parts in a safe place.

Unfortunately there are no aftermarket screws available for ‘vintage’ Guild guitars, so as a repairman I would have no problem using a screw with the correct thread that would work as well as the original did. I could live with the ‘looks’ as long as it will keep the pickup in place; meanwhile one could search for something that looks closer to original.

For the HB-1 pickup Guild basically used two different height adjustment screws with a distinctive head shape.

Here are some photos that shows the two different styles.

Over the years there were several small variations in size, but you would only notice the difference by actually measuring them.

Sincerely,

Hans Moust

www.guitarsgalore.nl

- Joined

- Feb 11, 2009

- Messages

- 22,991

- Reaction score

- 18,635

- Location

- NJ (The nice part)

- Guild Total

- 112

Hans always has the best data.

At this point I can't even find gold-plated #4-40 machine screws of any kind.

At this point I can't even find gold-plated #4-40 machine screws of any kind.

SFIV1967

Venerated Member

The screws from poa77 out of UK arrived! I have to say I am very impressed as they are very close to the original and top quality! And to be honest, all the pictures poa77 posted both on ebay and here somehow look far worse than the screws I got from him! Not sure why that is, but I will take the time posting some macro pictures of them vs. the two type "original" screws I have. Even the slots look cut very clean. I'm not sure I would even bother to make the head flatter in my case. The screws GAD got look far worse quality to me. So using 6 of poa77 screws seems to be a perfect solution for a guitar and one won't notice anything wrong with them. The one thing I noticed without exactly meauring them yet is that the cut slot is slightly wider (but very clean and very parallel) compared to the original screws. Pictures will tell, can't promise I find the time in the next fews days this week to prepare them however. Probably not before the weekend. But if one needs some, you can buy in confidence from poa77 in the meantime! I would recommand not mixing them old and new but to simply use 6 new screws.

Ralf

Ralf

Great ending

hi ralf, glad you're as happy with them as i was. as for the discrepancy between the pictures and the actual screws it's all down to my (lack of) camera skills, haha! btw i just wondered what guitar these were for? mine were for my S100 that arrived without the original pickups but still with the original surrounds.... but not the original screws. i sourced some original HB-1s but they too didn't come with any screws hence my search for some replicas. yes it's a bit beat up and has had extra holes drilled (now filled) for coil tap micro switches but i'm loving how it plays and sounds now it has the original pickups back in there. it's a fantastic guitar.The screws from poa77 out of UK arrived! I have to say I am very impressed as they are very close to the original and top quality! And to be honest, all the pictures poa77 posted both on ebay and here somehow look far worse than the screws I got from him! Not sure why that is, but I will take the time posting some macro pictures of them vs. the two type "original" screws I have. Even the slots look cut very clean. I'm not sure I would even bother to make the head flatter in my case. The screws GAD got look far worse quality to me. So using 6 of poa77 screws seems to be a perfect solution for a guitar and one won't notice anything wrong with them. The one thing I noticed without exactly meauring them yet is that the cut slot is slightly wider (but very clean and very parallel) compared to the original screws. Pictures will tell, can't promise I find the time in the next fews days this week to prepare them however. Probably not before the weekend. But if one needs some, you can buy in confidence from poa77 in the meantime! I would recommand not mixing them old and new but to simply use 6 new screws.

Ralf

SFIV1967

Venerated Member

Understand - I will rephrase. I am liking the direction this journey is going on

- Joined

- Feb 11, 2009

- Messages

- 22,991

- Reaction score

- 18,635

- Location

- NJ (The nice part)

- Guild Total

- 112

Nice. So if I'm seeing the original pics right, the head shape looks great but the slot isn't perpendicular. Is that accurate?

SFIV1967

Venerated Member

No. That's the odd thing. The screws I got look like the slot is perfectly perpendicular. That's why I am not sure why they looked so different (worse) in the pictures vs so good in reality. Maybe distortion from the lens when taking the pictures? I need a bit of time taking my pictures, it's hard to correctly take such macro pictures. I like the way Hans took the pictures.So if I'm seeing the original pics right, the head shape looks great but the slot isn't perpendicular. Is that accurate?

Ralf

- Joined

- Feb 11, 2009

- Messages

- 22,991

- Reaction score

- 18,635

- Location

- NJ (The nice part)

- Guild Total

- 112

Take some pics, man! If they're great I'll buy a freaking truck load of them.

Hell, I just went to three hardware stores. I can't even find #4-40 screws let alone anything that looks nice!

Hell, I just went to three hardware stores. I can't even find #4-40 screws let alone anything that looks nice!

SFIV1967

Venerated Member

Here they come. Hard with low light at night, also shows a lot of dust in macro mode...And again, in macro mode they look worse than in original size.Take some pics, man!

1 = The original screws. (as also shown as the two right side screws in Hans pictures above)

2 = The new screws sourced from poa77 in UK

3 = Another one that was on a HB-1 which almost looks like type 1 but has a narrower slot! Not shown by Hans.

4 = A standard humbucker screw size #3-48 (2.515 mm diameter) which is too thin for HB-1s but which has a similar head as the left two screws in Hans pictures.

1 to 3 are all #4-40 (2.845 mm diameter) and 1 1/8" (28 mm) long.

1 has a 0.035" (0.889 mm) wide slot. Very clean cut. (here just scratches from screwdrivers)

2 has a 0.034" (0.864 mm) wide slot (in the center). Parallel and still clean but visible "butterfly" marks on the edges from the press or hammers during production. (not so obvious in original size)

3 has a narrower 0.026" (0.661 mm) wide slot only.

Bottom line: That screw marked with number 2 in my pictures from poa77 is a good screw to use, espacially when used in sets of 3 per humbucker. They look pretty good to me and have the correct necessary dimensions even if they don't come close to the original pan head and slot on number 1 in my pictures.

poa77 seems to have plenty of them as he special ordered them from a screw manufacturer. See his ebay link.

Ralf

Last edited:

- Joined

- Feb 11, 2009

- Messages

- 22,991

- Reaction score

- 18,635

- Location

- NJ (The nice part)

- Guild Total

- 112

Thanks for the most excellent pics Ralf! From what I'm gathering, we may not be able to do much better than that. That's really bugging me, but I'm losing more hope by the day of ever finding perfect replacements.

I bet there's a whole box of those beautiful vintage screws sitting in a drawer somewhere just waiting to get thrown out.

I bet there's a whole box of those beautiful vintage screws sitting in a drawer somewhere just waiting to get thrown out.

SFIV1967

Venerated Member

If both Hans and Ken Nash have no source that tells something...I bet there's a whole box of those beautiful vintage screws sitting in a drawer somewhere just waiting to get thrown out.

Ralf

- Status

- Not open for further replies.